Setting The Stage For Production

This software is an external verification/optimization tool that provides faithful representations of first-run machining processes. This affords the opportunity to rectify machining conflicts before the first chip flies.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreThe conventional response to a machining error is to diagnose the cause after the damage is done. But this approach entails some key drawbacks. In the first place, delays or disruptions in production represent the most costly events that occur in machine shops. The attendant costs of ruined cutting tools, damaged spindles or scrapped parts also represent major concerns.

Given these risks, using software tools to simulate actual machining operations represents a distinct advantage in process management. Performing dress rehearsals for metalworking's main events is precisely the capability provided by Vericut verification/optimization software manufactured by CGTech (Irvine, California).

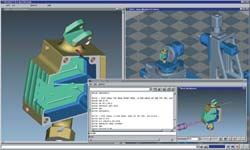

The verification functions embedded in many CAD/CAM systems check only the internal CAM files. Because these files may be subject to additional translation before reaching the machine controls, errors can sometimes creep into the process. Vericut is an external verification/optimization tool that provides faithful representations of first-run machining processes. This affords the opportunity to rectify machining conflicts before the first chip flies.

Because the program's simulations are driven by the same control logic and data that drive machine tools, virtual prove-outs conform precisely to the actual machining. Thus, a virtually machined "part" may be compared for conformance to the original design model before any metal is cut. The virtual "as-machined" CAD model may also be exported back to the CAD system for other uses such as designing mated parts or planning subsequent operations.

The Vericut software package comprises seven add-on modules that run on Windows and UNIX platforms. These modules allow users to customize packages to serve specific needs. For example, the OptiPath module allows the feed rates to be adjusted to suit the changing cutting conditions for more efficient tool paths. A separate Auto-Diff module enables the user to virtually embed the design model (including tolerance offsets) within the raw stock. If the virtual tool broaches this tolerance envelope, the program automatically reports the error and highlights the gouge.

The Machine Simulation module creates and operates virtual machine tools and controls. In addition to the features offered in the software's 5.1 version, CGTech has developed Vericut 5.2 with new and enhanced capabilities. The software incorporates a review function that allows the user to replay either the entire tool path or only a particular segment. This enables the user to review critical portions of the tool path, as well as to display the cutting tool at the precise location of the error. During this process, the NC program code (G-code or APT file) is displayed beside the graphics. This enables the user to edit the NC program on the fly as the virtual prove-out continues.

Other improvements in the 5.2 version are a new Mastercam interface and an enhanced Unigraphics interface. The interfaces allow tool paths to be verified at the same time that the user continues to work in these programs. Besides simulating and verifying milling, turning, drilling, mill/turn and wire EDM tool paths, the new version adds a die-sinking function. This function checks for electrode gouges and over- or under-burn conditions. It also analyzes the volume of material removed by each electrode, the contact area and electrode overlaps.

In addition to upgrading existing Vericut functions, the 5.2 version also simulates turn-threading operations and supports boring bar cycles. A new Comparator function enables users to overlay circular or rectangular grids onto the cut model for quick visual measurements. The program's Curve Fitting function reads NC programs to detect sequences of planar motion, thereby fitting arcs to smooth linear motion. This "pre-processor" helps to improve surface finishes and reduce machining time.

By simulating, verifying and optimizing their production processes, machine shops can reduce the time and expense that accompany a trial-and-error approach. Furthermore, using virtual dry runs to test part programs ensures that the first runs will be successful.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)