Machine Tools Used As Dedicated Equipment…For A Little While

Two keys to this shop’s success are versatility and speed. It uses flexible machining centers, rather than dedicated equipment, and constantly reconfigures them into new cells for new jobs. The speed at which it can do this, in addition to in-house tombstone manufacturing capability, provides the nimbleness to quickly respond to its customers’ needs.

Share

Machine tools don’t sit idle for very long at Busche. For that matter, they might not stay located in the same spot or even the same company building once a job has ended.

Busche (pronounced with a long “e”) has a total of 220 CNC machines in six production facilities in and around Albion, Indiana. Horizontal machining centers (HMCs) represent the largest portion of that capital. The company currently has 97 HMCs, the vast majority of which are from Okuma (Charlotte, North Carolina).

The privately held company primarily performs mid- to high-volume machining work for the automotive and construction industries. Nick Busche, company president, admits that dedicated equipment would likely complete some jobs quicker than his machining centers. However, he believes the flexibility those machining centers offer to perform a wider variety of work is more important than faster production. To that end, the company has become adroit in reorganizing machines into new cells as existing jobs reach end-of-life and new ones begin. That’s also why the shop, which runs 24/7 with 450 employees, has yet to justify the use of machine-tending robots. It has found that well-trained personnel, like machine tools, are easier to redeploy.

This strategy is paying off. Busche was a $6.5 million company in 1999. Its projected sales for 2007 are $54 million. Flexibility, speed and in-house resources such as tooling, training and machine service have contributed greatly to this success.

Growing Steadily

Mr Busche created his company in 1998. Over the years, the company has formed relationships with select forgers and die casters such that 90 percent of its work is purely value-added machining. That shields the company from absorbing the hit of rising material costs. Automotive work represents 50 percent of its business, down from 70 percent in years past. Except for his first few years in business, Mr. Busche hasn’t dedicated more than 15 percent of capacity to any one customer.

In 1999, Mr. Busche merged his business with his brother Jerry’s tooling company, which became the Busche Workholding division. That division specializes in designing and manufacturing hydraulic tombstones. Having in-house tombstone manufacturing capability for the company’s HMCs allows it to ramp up for new jobs in short order. Mr. Busche says tombstones have been designed and delivered in as little as 3 weeks, versus the 12- to 16-week lead time that’s typical when using an outside tooling vendor. This helps the company reach full production levels on new jobs in as little as 6 to 8 weeks. The Busche Workholding division also supplies tombstones to outside shops. In fact, that outside work represents 80 percent of the division’s business.

The company also has in-house machine service. Gosiger Inc., Busche’s machine tool distributor, maintains a two-person office on-site at Busche. With ever-shrinking delivery schedules, same-day machine service is crucial. If a machine is not making chips, it’s not making money.

Cells And Communication

Busche continually adds and/or reconfigures existing machine tools into new cells that are temporarily dedicated to a new job. Busche performs all the project management to determine an effective layout and power requirements. It then hires electricians to put in new drops and riggers to move machines into position. Gosiger technicians assist in leveling and other final installation duties.

Each machining cell is set up with all gaging and other necessary equipment for a particular job. Oftentimes the cells include value-added operations, such as pressure testing for rack and pinion housings, bearing installation, assembly, parts washing and so on. Some cells even include a CMM housed in a compact, air-conditioned enclosure. The company, which is registered ISO/TS 16949:2002, has a total of 14 CMMs.

All parts are traceable back to the machine operator, and the company demands accountability for all parts it ships. For example, if a bad part is returned from a job that required 100-percent inspection, then that operator could be terminated. The company looks at that as an act of insubordination. That’s why it provides to cell operators all information needed for a particular job. Currently, part prints, work instructions and other data are provided in the form of laminated printouts.

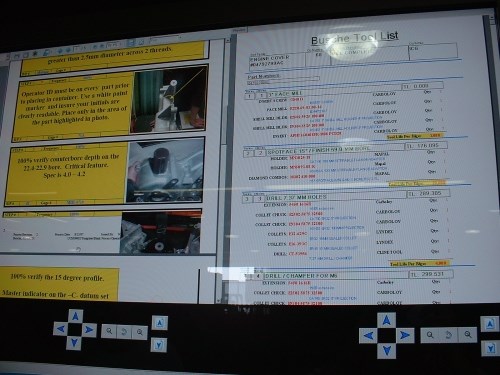

However, this paper-based medium is being phased out. The company is starting to add 50-inch, touchscreen monitors in each cell, offering access to all job data in a large, digital format. Because revised job information can be quickly uploaded to a job file, operators—and Busche customers—are assured that the most current data is being provided. Although the company is in the initial stages of adding these cell monitors, it eventually will have approximately 100 such touchscreens.

Communication works both ways, however. Each plant has a dry-erase board where employees can list and date specific problems they experience. Such a visual tool spurs corrective action by making all company employees from owners to operators aware of issues that have been identified.

Central Store

Originally, each Busche plant had its own tool crib. On the surface, this might make sense because the facilities are in spread out in different locations. However, maintaining separate tool cribs made tool inventory and usage difficult to track. To eliminate waste and offer better control over tooling and other shop supplies, the individual tool cribs were removed from the facilities and consolidated into one central store serving all plants.

Each plant now includes a compact ToolBoss tool crib/inventory management system from Kennametal (Latrobe, Pennsylvania). Operators must input a part number from a job tool list and scan an identification card before a tool can be pulled. Collected at the central store, this data can be used to create various types of usage and cost reports. Such complete documentation means correct tool inventory numbers are maintained.

All damaged tools are also collected at the store. And each day, managers perform a tool review after their normal production meeting to identify and diagnose repeating tool problems. In addition, the store includes a grinding machine for tool resharpening.

In-House Education

In the summer of 2004, Busche launched plants 6 and 7 (plant 7 is dedicated to turning work). To support those plants, it had to hire approximately 245 people in a span of just 45 days. Training such a large number of employees in such a short amount of time was no walk in the park. Realizing further expansion was likely coming, and not wanting to go through that situation again, the company decided to create its own metalworking training facility. Busche’s educational center, located away from its main Albion campus, went live in 2005.

The facility includes a number of computer workstations running shop training software from MasterTask Training Systems (Rockford, Illinois). Busche uses three MasterTask training modules—measurement, CNC lathes and machining centers—which require 10, 22 and 25 hours of study, respectively. Employees often schedule time to train before or after their work shift. Because the classes are held off site, there is less chance for workplace distraction. To date, 105 employees have successfully completed all three training modules, and the vast majority has stayed with the company.

The educational facility also houses a CMM, a granite table with gaging equipment and an AV-equipped meeting room. Mr. Busche says the investment to create and maintain this resource is small relative to the payback. Plus, the educational facility serves as a good sales tool for potential customers. Mr. Busche says his customers want to form long-term partnerships with machine shops. Such an investment in training demonstrates that the company is not only committed to success, but is in it for the long haul as well.

Preparing For Future Growth

Mr. Busche wants his company to be one of the major players in value-adding machining. That means more expansion is on the horizon. Some Busche customers are asking the company to locate closer to their production facilities. Mr. Busche would prefer to acquire existing shops near his customers and integrate his company’s philosophies into the new division. The goal is to grow Busche to become a $250 to $300 million business.

He says the work is out there.

Related Content

How to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreAddressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)