Articles

Why Tie Payroll Hours to Machine Tool Hours?

J&R Machine uses machine-monitoring data not just to track machine uptime, but also to create a financial index that helps it shape decisions related to equipment, processes, staffing, sales and business in general.

Read MoreShop Hits Home Run with Toolpath Simulation Software

Wolcott Design Services needed to improve efficiency during high-mix, low-volume runs. HMCs and Vericut tool simulation software by CGTech improved efficiency, spindle utilization and revenue.

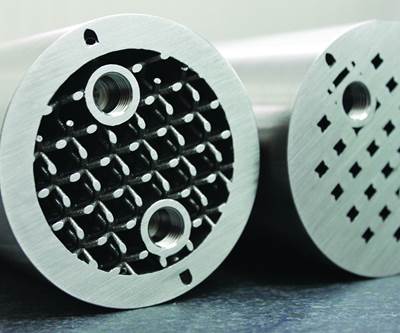

Read MoreLightweighting with Lattices

Instead of building components as a solid, building them as a network of unit cells may improve material utilization and performance.

Read MoreYour Chance to Affect Policy Change

Complete the U.S. Manufacturing Reshoring Study survey to provide politicians with insights into how much manufacturers offshore and what drives them to do so.

Read MoreWe Are Investing in the Print Magazine

We are doing so because our audience is there. Some findings suggest that’s not likely to change soon.

Read MoreBuying a Five-Axis: The Costs and Benefits of a Complex Machine

When considering transitioning to a five-axis machining center, it is helpful to understand the basics about the machines’ components, their costs and the opportunities they provide.

Read MoreTraceability Without the Paper Trail

A digital system makes it faster and easier to find, sort and glean insights from measurement tool usage and calibration data.

Read MoreVideo: Between Casting and Machining from Solid Is Extrusion

The Machined Direct Drive Pedal from DW Drums realized design improvements thanks to machining, then cost improvement as result of moving one step further.

WatchSeeing Smart Manufacturing in Taiwan

A recent visit to Taiwan revealed new smart-manufacturing technologies being developed by the island’s machine tool builders as well as by its largest commercial and military aircraft manufacturer.

Read MoreTracking Time with Custom Macro

System variables allow for time-based applications like tool-life monitoring, preventive maintenance, sampling inspections and machine warm-up.

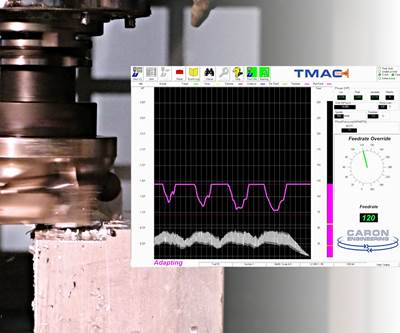

Read MoreFor Titanium, Tool Monitoring Smooths Low-rpm Cuts

Caron Engineering’s TMAC MP has been putting tool monitoring to work for years, but its “sawtooth algorithm” now meets a specific challenge in airplane engine machining.

WatchWhat to Know About Surface Finish Measurement

Texture is viewed differently by different manufacturing professionals, but the parameters for describing it are standard.

Read More