Seeing Smart Manufacturing in Taiwan

A recent visit to Taiwan revealed new smart-manufacturing technologies being developed by the island’s machine tool builders as well as by its largest commercial and military aircraft manufacturer.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Kurt Manufacturing Company

Featured Content

View More“Smart manufacturing” is one of many broad-brush terms describing the collection and use of production data to make better, more informed decisions to improve efficiencies on the plant floor. In our world, this relates to obtaining data from networked machine tools and ancillary shopfloor equipment to assist with tasks such as job scheduling, maintenance planning and overall shop communication and continuous improvement efforts.

During a recent visit to Taiwan, I learned that the Taiwanese government has deemed its machine tool industry to be of national strategic importance and, as a result, continues to support initiatives to place Taiwan at the forefront of connectivity and smart manufacturing technology. Much of the country’s machine tool builders’ efforts in this regard revolve around new machine tool control technology/human-machine interfaces (HMI), Industrial Internet of Things (IIoT)-based production management, and cloud-based remote monitoring and preventive maintenance. Here are a few examples of these efforts:

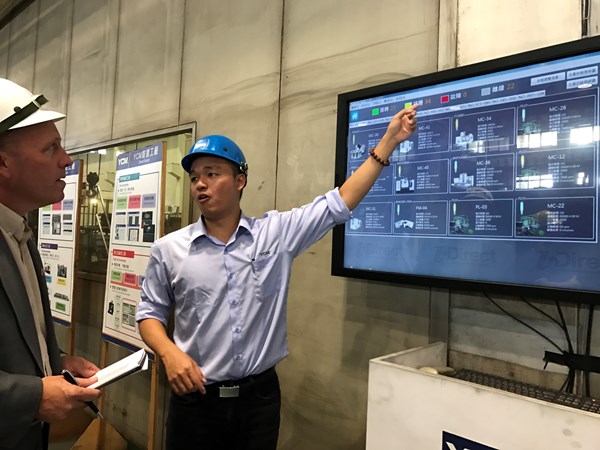

YCM

Before offering its iDirect IoT platform to customers, YCM first developed and refined it on its own production campus, which includes a foundry for castings and production areas for spindle manufacturing and machine assembly. Using iDirect, its customers’ shop managers and owners are said to be able to easily track production status, manage facility utilization and monitor overall equipment effectiveness (OEE). This technology enables shops to link machine tools using various CNCs, as well as manual equipment, to collect production data for real-time shop management and monitoring.

In addition, YCM continues to build intelligence into its wide-ranging machine lines to optimize machine performance and longevity. For example, intelligent spindles and drive systems are said to enhance cycle times while minimizing vibration to help ensure quality surface finishes and extended tool life, while other functions monitor equipment heath with the goal of predicting component failure to enable shops to schedule maintenance operations before a sudden failure disrupts production.

Goodway

Goodway manufacturers horizontal and vertical turning centers, which are branded as Yama Seiki in the United States. Rebecca Hsieh, Goodway vice president of sales, says the company has recently introduced the second generation of its G-Linc 350 HMI for its machine controls. This version of G-Linc 350 features a 21-inch touchscreen and offers remote access to information related to tool management, machine load monitoring, machine sensor status and so on. It is also said to simplify the integration of manufacturing execution system (MES) and enterprise resource planning (ERP) software while 3D-simulation capabilities shorten setup times for new jobs.

Fair Friend Group

Fair Friend Group (FFG) has grown by acquisition, and now has 37 different machine tool brands. Recently, FFG and Siemens have signed a joint memorandum of understanding with the intention of strengthening their long-standing business relationship. The aim of the extended partnership is to consolidate the integration of the Siemens Digital Enterprise Suite across the entire FFG business and to integrate Siemens digitalization and automation technologies into FFG’s machine tools and machine tool technologies. The two businesses agreed to work closely together in the future on the consolidation of the Siemens Digital Enterprise Suite and the cloud-based Internet of Things (IoT) operating system MindSphere at FFG.

In addition to implementing such smart manufacturing initiatives, FFG has also began implementing smart marketing. It it increasingly using augmented and virtual reality in these efforts, the latter of which enables customers to walk around and go inside virtual representations of its machine tools as well as access information and specifications about the machine.

Cosen

CNC band saw manufacturer Cosen worked with Intelligent Maintenance Systems (IMS), a U.S.-based research center located at the University of Cincinnati, to develop its SawLogix cloud-based predictive maintenance app that not only monitors saw blade live, but predicts blade failure, too. It also monitors overall band saw machine health in real time. The goal was to eliminate the need to track machine hours and accumulate cut data to get a rough idea as to when a blade might need to be replaced. Accelerometers mounted on the machine detect vibration that might indicate when a blade is starting to fail, while other sensors are used to adapt to abnormal conditions from motors or bearings or provide alerts related to consumable items such as hydraulic oil and cutting fluid. This information, as well as information such as machine status, number of cuts performed, time remaining to complete a job, blade life remaining, etc., is accessible on smartphones and tablets through the SawLogix app. SawLogix can be retrofitted to existing Cosen saws as well as other brands of CNC saws. In addition, Cosen has started another business, MechaLogix, to explore similar cloud-based predictive monitoring apps for other types of CNC machines.

Quaser

Quaser manufactures automation-friendly five-axis machines as well as vertical machining centers, horizontal machining centers (all with hand-scraped ways) and flexible manufacturing systems (FMS). It has developed a paperless process for machine assembly in which the assembler (there is only one per machine for accountability purposes) accesses information from and inputs information to the shop management software it developed via a tablet device. This paperless process enables assembly time to be easily tracked and ensures the latest drawing revision is available to the assembler.

Quaser also offers shop management software for its machine tools, too. This software enables access to job-specific information related to the part itself, fixturing, tooling and part programming as well as information such as job scheduling and prioritizing. The company opened its own U.S. location in Rock Hill, South Carolina, in late 2016 (although it had been using an importer for a number of years prior to that). This year will be the first time it will have its own booth at the International Manufacturing Technology Show (IMTS) in Chicago, Illinois.

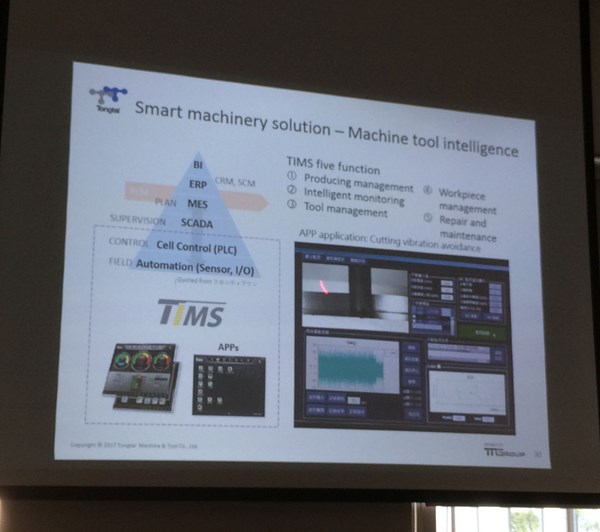

Tongtai

Tongtai has also grown through acquisition, and the Tongtai Group now includes Asia Pacific Elite Group (APEC), Honor Seiki, and Quicktech, as well as Europe’s Anger and PCI. In terms of smart manufacturing, the company had developed its Tongtai Intelligent Manufacturing System (TIMS), which has five main functions: production management, smart monitoring, tool management, component management and maintenance. TIMS can process the data received by sensors to control and adjust machines or provide feedback to operators for functions such as machine load monitoring, cutting tool load monitoring, cutting tool life management, machining adaptive control, machine alarm messaging and maintenance support. The company also offers additive and laser cladding capabilities to enable manufacturers to make smart decisions about how best to produce their products.

AIDC

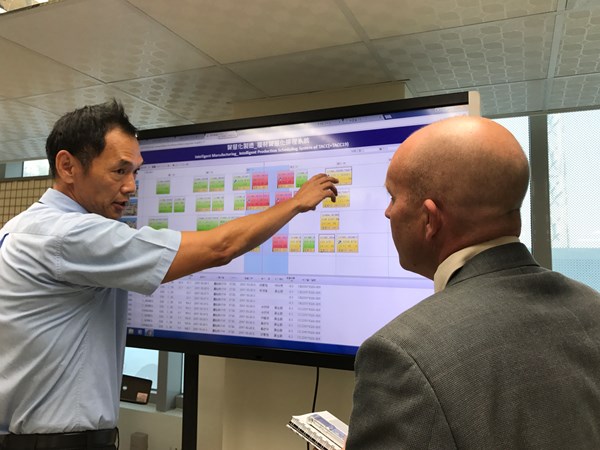

The formerly government-owned Aerospace Industrial Development Corp. (AIDC) is the type of company for which machine tool builders are developing their smart manufacturing technologies. In fact, AIDC, Taiwan’s largest civilian and military aircraft manufacturer, has developed its own Intelligent Manufacturing platform to monitor all four of its manufacturing locations as was shown to me at the company’s Taiwan Advanced Composite Center (TACC) campus.

The system enables real-time monitoring on site (or remotely via smartphone or tablet device) of all aspects of manufacturing processes, with capability to drill down to examine the status of an individual machine tool or piece of equipment, such as an autoclave. This is helpful in a number of ways, one being that it helps scheduling. For example, the four autoclaves at the TACC complex are what drive upstream processes including composite material layup. Careful monitoring of autoclave cycle times ensures those processes are scheduled at the proper time to minimize autoclave downtime.

AIDC is also looking to develop a smarter, wider supply chain of local suppliers regarding raw material and machining vendors with one goal being to reduce logistics costs associated with using vendors outside the country. The company works with various local suppliers that haven’t traditionally served the aerospace industry helping them attain certifications such as AS9100 that are required by aerospace original equipment manufacturers. Dubbed “A-Team 4.0,” this alliance matches the capabilities of each member company with specific manufacturing demands to increase the number of potential suppliers to create competitiveness to reduce costs. The alliance currently has more than 330 member companies.

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreRead Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)