Aerospace Machining

Aerospace machining is frequently characterized by the tight tolerances and hard-to-machine metals typical of aircraft engine components, as well as the complex contours typical of both turbine blade forms and the aerostructural components making up a plane’s form. Because machined contours are so typical, five-axis machining is routine in this sector, include large-travel five-axis machine tools able to accommodate the largest aircraft structural components. Materials typical of aerospace machining include lightweight aluminum for structural members; hard and temperature-resistant metals including titanium and Inconel alloys for engine parts; and carbon-fiber composites that are both hard and lightweight for outer skins. Along with large five-axis machines, turn-mill machines and precision grinders are among the high-value machine tools routinely used in this sector.

Latest Aerospace Articles

VIEW ALLForkardt Hardinge Swiss Workholding Provides Reliable, Consistent Performance

The company’s Swiss collets are designed to securely hold parts without marring surfaces, minimizing vibration to ensure smoother machining, enhanced accuracy and extended tool life.

Read MoreKennametal Turning Tools Enhance Small Part, Medical Machining

TopSwiss Micro Boring Solid tooling and KCU25B turning inserts are well suited for the small parts and medical machining space.

Read MoreAFRC, ATI Partner to Boost Aerospace Materials Innovation

ATI Inc. has joined the University of Strathclyde’s AFRC as a tier one member, aiming to develop metallic alloys that support sustainability in the aerospace sector.

Read MoreGrob Announces Aerospace Technology Event

At the Aerospace Technology Day event — which takes place at Grob’s facility in Bluffton, Ohio, on November 19th, 2024 — attendees will see five-axis aerospace parts machined live, be able to consult with a panel of technical experts and more.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreThe Role of Surface Finishing in Modern Manufacturing: Trends and Best Practices

You’re attending IMTS to advance your business. Regardless of your role in the manufacturing process, considering how your parts will be finished is crucial. This article can help you understand trends in surface finishing and better communicate with your finishing partners.

Read MoreLatest Aerospace News And Updates

How a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

Read MoreSchwanog Custom Form Tools Reduce Cycle Times

IMTS 2024: Schwanog’s insertable form tool system supports the manufacture of precision parts for industries such as medical, automotive, aerospace and others.

Read MoreSandvik Coromant Inserts Provide Stable Turning of Aerospace Components

The new insert grades GC1205 and GC1210 cover a large application area within last-stage machining and intermediate-stage machining when turning aerospace engine components.

Read MoreJR Machine Launches Expansion Strategy, Hires New CEO

An investment from Schneider Resources Holding positions JR Machine to grow in emerging markets such space exploration and green energy.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreBavius Technologie Appoints New President, Schedules Technology Showcase

Roy D. Cripps will lead the team at Bavius as it aims to expand its current business in aerospace structures and develop new market segments. Additionally, the company will showcase its technology during an open house event on June 11.

Read MoreFeatured Posts

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

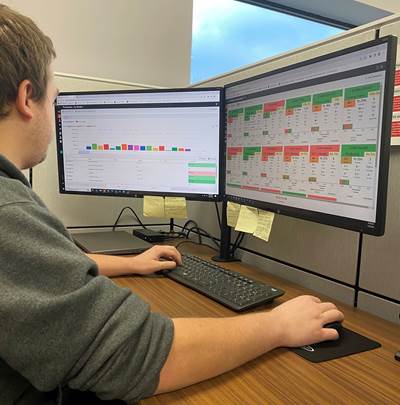

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read More10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read More

.jpg;maxWidth=300;quality=90)