The Role of Surface Finishing in Modern Manufacturing: Trends and Best Practices

You’re attending IMTS to advance your business. Regardless of your role in the manufacturing process, considering how your parts will be finished is crucial. This article can help you understand trends in surface finishing and better communicate with your finishing partners.

Share

At the International Manufacturing Technology Show (IMTS), industry professionals gather with a shared goal: advancing their businesses. Regardless of your role within the manufacturing process chain, it’s impotant to prioritize the finishing of your parts from the outset. Whether you manage finishing in-house or rely on outsourcing, early consideration of the final finish will help ensure quality.

The traditional approach of merely machining parts and sending them to a metal plater is outdated and should be left in the past. To achieve the highest quality, it’s essential to collaborate closely with every partner in your process chain, including surface finishing experts.

What are the current trends in surface finishing? Industry professionals are focusing on several key areas that shouldn’t come as a surprise.

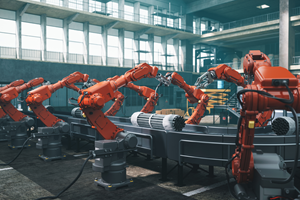

GrayMatter Robotics provides artificial intelligence (AI)-driven software designed to enable robots to program themselves to perform surface finishing and surface prep operations for a wide variety of part sizes and shapes. Source: GrayMatter Robotics

1. AI, machine learning and IoT solutions

Much like other areas of manufacturing, finishers and coaters are seeking ways to streamline their processes. Today, finishers are increasingly exploring robotics, artificial intelligence (AI) and machine learning to tackle challenges such as workforce shortages, quality control and repeatability.

Historically, finishing operations have been slower to adopt IoT and automation solutions due to the high mix of parts typically processed by job shops, but various factors — including workforce trends and demands for environmentally responsible and sustainable processes — are accelerating the need to find new efficiencies.

Discover how one company is using AI to make finishing processes for a high mix of parts of varying geometries as easy as the push of a button. short.pfonline.com/graymatterAI

These lattice cubes were 3D printed from clear resin using stereolithography, then coated by RePliForm with electroless nickel, copper and layers of ductile and hard nickel to improve their compression performance. Source: Additive Manufacturing

2. 3D Printing

Additive manufacturing is growing exponentially. As this technology continues to move from the realm of R&D and short run production to full scale production, an increasing number of fabricators are looking to various finishing methodologies to not only protect parts or provide aesthetics but in some cases to increase functionality.

Check out a story about how one company is using electroplating to enhance the physical properties of additively manufactured parts. short.pfonline.com/repliform3D

EVs present exciting new opportunities for additional growth of the use of electroless nickel plating in the automotive market for several critical components. Source: Getty Images

3. Electroless Nickel Plating and EVs

The advent of electric vehicles (EVs) seems to have finally arrived. With a growing number of automotive OEMs investing in new capabilities to grow their EV and hybrid offerings, finishes will be needed for a range of parts from electrical motor components to batteries.

One example is electroless nickel (EN) plating. EN has been used in the automotive industry for decades. Applications include piston heads, carburetors and fuel injection components, slip yokes and transmission components. Today, EVs present exciting new opportunities for additional growth of EN in the automotive market with the finish being used for several critical components used in electric vehicles.

Learn more about the role EN is playing in the developing EV market: short.pfonline.com/ENandEV

Powder coating overspray can be reclaimed and reused. Source: Innovakote

4. Environmental Considerations

Contrary to some perceptions, environmental concerns are a priority in the finishing industry. As one of the most heavily regulated sectors in manufacturing, compliance is essential for the industry’s sustainability. For years, metal finishers have been engaged in negotiations with environmental groups to address issues related to air quality and wastewater treatment. The industry has been proactive in seeking alternatives to potentially harmful hexavalent chromium finishing technologies, exploring safer options like trivalent chromium-based processes. The evolving regulatory landscape will continue to influence the available finishing technologies and their application methods.

This Products Finishing Ask the Expert column, discusses the environmental considerations driving some of these regulations: short.pfonline.com/hextotrichrome

In terms of coatings, powder coating has always been a low volatile organic compound (VOC) approach to coating parts, and powder overspray is a reclaimable material. Despite its already environmentally-friendly nature, new ways of making powder coating even more sustainable are being explored.

Check out this story about two companies that have found novel approaches to reclaiming powder. short.pfonline.com/reclaimpowder

This 3 D printed radar array is PAEK plated with layers of copper and electroless nickel using a plating on plastic activation chemistry known as GreenPOP. Source: Alliance Finishing and Manufacturing

5. Plating on Plastics

Plating on plastics (POP) isn’t new. Electroplating on plastic typically involves the process of depositing a thin layer of metal onto a plastic substrate using an electrochemical process after first preparing the plastic for the metal to adhere. Advances in plating on plastics, as well as the introduction of new materials aimed at producing lightweight parts are creating opportunities beyond traditional POP applications, which are often decorative in nature. Today, POP is being explored for use in diverse industries, including aerospace, automotive and electronics. The ability to electroplate on high-performance resins, lightweight composites and additively manufactured parts opens new avenues for innovation, making plating on plastic an option for enhancing functionality of parts in addition to providing esthetics.

Learn more about new innovations in plating on plastics: short.pfonline.com/GreenPOP

Finishing today and tomorrow

The finishing industry is integral to the broader manufacturing landscape. Consumer needs and buying trends shape not only what we produce but also the methods we use. To ensure the highest quality for your parts, engage with your surface finishing partners early in the production process. Leverage their expertise to achieve the best possible surface finish, aligning with industry standards and consumer expectations.

Related Content

Increasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)