Machining Centers

Through-Coolant Capability Reduces Cycle Time

Aided by Walter Titex tooling and a new higher-rpm machine tool from Fryer, Toolmasters Inc. was able to cut cycle time on a complex die set.

Read MoreMulti-Pallet HMCs Reduce Setup Time

Incorporating Kiwa horizontal machining centers from Methods Machine Tools helped Baum Precision Machining Inc. reduce setup time and improve productivity.

Read MoreTool Monitoring for Multitasking Machines

Continuously checking the condition of cutting tools and responding appropriately to wear or other changes is especially critical on machines designed to complete parts in a single setup or run several operation simultaneously.

Read MoreAdopting a 24/7 Mindset

This shop considered a number of factors before establishing an effective process to run an HMC cell around the clock for applications in aerospace, oilfield and other industries.

Read MoreFrom Media to Manufacturing

Video producers with no previous knowledge of CNC discover the power and possibilities of modern machine tool technology. Their example says something about where manufacturing talent might come from, and also about the importance of manufacturing as a whole.

Read MoreFlexible Manufacturing System Shortens Lead Times

A Makino MMC cell and a81 machines provide a flexible production environment that helped Roush Industries take on a wider variety of work with shortened lead times.

Read MoreFive-Axis Machine Offers High Dynamics for Complex Workpieces

The Heckert HEC 800 X5 MT five-axis machining center, available from Starrag, provides productivity, process reliability and precise cutting in a single clamping.

Read MoreMachines Offer Parallel Kinematics for Aluminum Components

Dörries Scharmann Technology (DST), a subsidiary of Starrag Group, extends its Ecospeed range of parallel kinematics machines for productive machining of aluminum structural components in the aerospace industry.

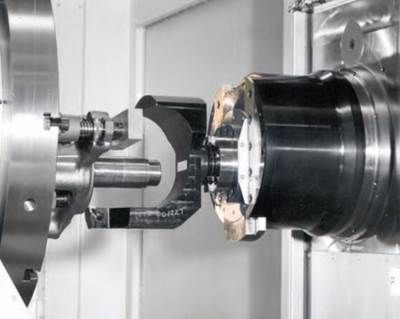

Read MoreHMC Delivers Turning, Drilling, Milling with Single Clamping

The Heckert DBF 630 HMC, available from Starrag, enables turning, drilling and milling of non-rotational, asymmetrical parts in a single clamping with one toolholder.

Read MoreHow Much Can Unattended Production Add?

Using a horizontal machining center, this shop kept production going through two 10-hour shifts per day. That seemed like a lot, but a pallet system enabled the shop to go even further.

Read More

.jpg;maxWidth=300;quality=90)