Tool Monitoring for Multitasking Machines

Continuously checking the condition of cutting tools and responding appropriately to wear or other changes is especially critical on machines designed to complete parts in a single setup or run several operation simultaneously.

Share

Machine tools designed to combine milling, turning and other metalworking processes have remarkable potential for efficiency and productivity. Completing parts in one pass across a multitasking machine streamlines production by eliminating multiple setups, avoiding errors when parts are refixtured and performing several operations simultaneously. Multitasking machines also are well-suited for running unattended or having one operator oversee multiple units.

By their nature, multitasking machines tend to be complex and sometimes difficult to understand, however. They follow a variety of configurations—mills with turning, lathes with milling, twin-spindle machining centers and three-turret lathes are a few examples. Additional axis motions such as a rotating milling head (B axis) and turrets on a cross-slide (Y axis) compound this complexity.

And multitasking machines impose distinct challenges to cutting tool usage and management. For example, multitasking machines may have a limited number of stations for cutting tools on the tool turret or automatic toolchanger. Certain cutting tools may be called upon for both milling and turning operations. A worn or broken tool that interrupts a multitasking machine may have the same effect on productivity as unplanned downtime on two or more single-purpose machines.

Systems designed to monitor a tool’s condition, adjust automatically for wear and capture information about the tool’s performance can be especially valuable on multitasking machines. One of the biggest challenges to tool monitoring on a multitasking machine is coping with simultaneous cutting operations. One system designed specifically to meet this challenge is TMAC-MP from Caron Engineering (Wells, Maine) which stands for Tool Monitoring Adaptive Control for Multi-Process machines.

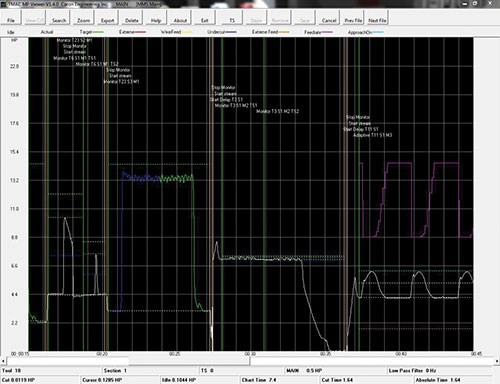

This system, which includes sensors installed on the machine tool and software installed on the CNC unit, monitors tool performance to detect wear or breakage, automatically adjusts feed rates to compensate for wear (adaptive control), and captures data about tool life. Several tools cutting at the same time can be monitored and controlled equally well, with all data recorded and displayed in a centralized interface. Data from a TMAC-MP system on an individual machine can be transmitted to a shop-wide machine monitoring system, enabling managers to incorporate critical tool data into calculations of overall equipment efficiency.

A Multi-Processing Extension

TMAC-MP is an extension of Caron Engineering’s pioneering TMAC tool monitoring system. It is based on the principle that a machine tool has to work harder to maintain a set feed rate as the edges of a cutting tool grow dull. In other words, spindle horsepower gradually increases as wear occurs. By sensing spindle horsepower output, the system can detect if a cutting tool is worn or broken.

More importantly, the system can be set to react to changes in the horsepower readings. If the power monitor detects evidence of excessive wear, it can signal the machine control to issue an alarm, initiate a tool change to retrieve a fresh spare tool or stop the machining process altogether.

The adaptive control option enables the control to automatically adjust the feed rate to maintain a constant horsepower rating as the tool undergoes normal wear patterns. As a result, the cutting tool performs at its optimum power level, thus extending its life, reducing cycle time, and avoiding stress on the spindle bearings and other machine components. Under this protocol, feed-rate adjustments are made constantly in small increments (typically 1 percent of the programmed feed rate) for a smooth transition that further protects the tool and workpiece surface.

For both monitoring and automatic adjustment, the system’s software can “learn” the normal horsepower draw for a given tool and operation while the tool is cutting. Using this baseline, the user can set limits and establish the preferred response.

The multi-processing enhancement of the system is designed to perform these functions even when multiple tools are cutting at the same time. Essentially, the software was reformatted to be multitasking in its own right. For example, this development enables the system to monitor and control two turning tools cutting simultaneously in an upper and lower turret while a milling tool is doing end work on a part in the subspindle.

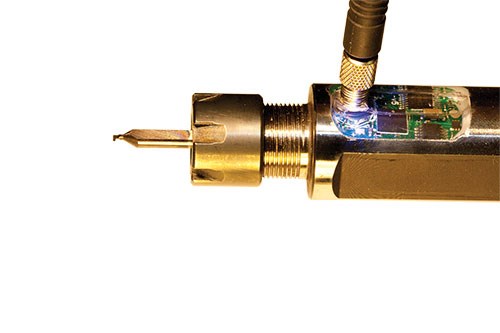

Originally developed for a Tsugami Swiss-type lathe and introduced at IMTS 2012, TMAC-MP also includes significant hardware innovations. Most important is the ability to monitor very small tools such 0.004-inch- (0.1-mm-) diameter drills. To this end, Caron Engineering had to develop new strain sensors that can be fully embedded in static toolholders sized for tools this small. The company also developed three-axis and single-axis accelerometers for measuring vibration. Mounted on the spindle or tooling slide, these sensors record vibration in spindle bearings, servodrives and other machine components that can adversely affect cutting conditions.

The system’s user interface was also changed so that machine and cutting tool data can be viewed in a bar graph that shows tool condition and remaining tool life for all tools being monitored. This information can be archived in any structured query language (SQL) database. The software can also be set up to send alarms by email or transmit them as text messages.

The Larger Connection

As valuable as tool monitoring and adaptive control may be for the individual multitasking machine, Rob Caron, president and founder of Caron Engineering, believes that the ability to port data across a network is the most substantial pay off awaiting shops and plants that implement the TMAC-MP system.

“Making tool data available to third-party software applications such as shopfloor machine monitoring opens doors to many possibilities such as plant-wide, data-driven decision-making and integrated automation,” Mr. Caron says. As a first step in this direction, his company is partnering with Memex Automation (Burlington, Ontario).

Memex’s manufacturing execution system, Manufacturing Execution Real-time Lean Information Network (MERLIN) supplies OEE metrics to support performance, productivity and profitability initiatives. The system tracks manufacturing operations bi-directionally from the ERP work order to each machine’s operations. MERLIN connects to all machines on the shop floor using various protocols, MTConnect adapters and/or network conductivity devices.

According to Mr. Caron, TMAC-MP users can use MERLIN’s interface and connectivity to deliver in-machine metrics from the shop floor to the operations and corporate executives, even to mobile devices or other web-enabled systems.

This connection also has the benefit of validating the productivity and efficiency gains delivered by multitasking machine tools, as well as making those machining resources more secure by detecting and preventing cutting-tool-based constraints to their full potential. “Multitasking machines and tool monitoring are more than complementary technologies. They are mutually empowering,” Mr. Caron concludes.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More