Machines

Integrated Pallet Changer Enables Continuous Operation

GF Agie Charmilles’ Mikron HSM 300 MoldMaster now includes the features and benefits of the company’s GraphiteMaster line. According to the company, the product consolidation enables users to choose between MoldMaster and GraphiteMaster configurations, increasing flexibility in the job shop. The mill features fast linear axes and a 30,000-rpm, high-frequency spindle.

Read MoreAutomated Turning For Small And Large Batches

The VL-Y from Emag is fully equipped with a Y axis (50-mm travel); a chip conveyor; a machining area extraction unit; a fluid-cooling system for spindle motor and turret; and automation equipment for loading and unloading workpieces. The machine features a recirculating workpiece storage conveyor on which “carrier prisms” deliver raw parts and collect the finish-machined components from the pick-up spindle. The pick-up station is located behind the machining area, so the operator can continue removing finish-machined components and inserting new raw parts into the carrier prisms at the front.

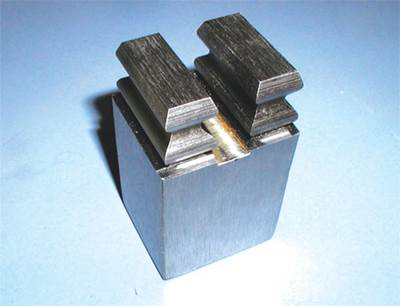

Read MoreRotary Indexing Spindle For EDM

Hirschmann Engineering has combined the H80R. MNCM high speed rotary indexing spindle with the H1625. AC3 fully programmable, variable speed AC control to produce miniature, round parts with small diameters and fine finishes.

Read MoreVideo: 56-Percent Productivity Increase By Reducing Chatter

The video compares a milling pass that chatters to one that is stable. Because the stable speed permits greater depth of cut, productivity increases.

WatchGrinding Turbine Rotors Has Advantages

For many aerospace components, grinding systems achieve greater productivity than milling and broaching on today’s lighter, tougher, harder materials. Tests performed at Saint-Gobain Abrasives’ Higgins Grinding Technology Center in Worcester, Massachusetts, showed that along with the latest abrasive and bonding technologies, the systems approach produced remarkable results when applied to grinding turbine rotor root-form slots.

Read MoreSide Turn-Milling Of A Massive Crankshaft

This video footage showing the machining of a massive crankshaft suggests some of the possibilities of turn-milling. Not all shops realize possibilities such as this even on their own smaller-scale turn-mill equipment.

WatchSoftware Supports Cell-Based Production Process

Implementing advanced manufacturing cells can help a shop improve productivity, but the cells themselves may be only part of the solution. That’s the case at Wilcox Industries, which combined advanced manufacturing capabilities of automated machining with the flexibility of Mastercam CAD/CAM software to keep up with continuing growth.

Read MoreJIMTOF Report: From the Field

The Japan International Machine Tool Fair (JIMTOF) is Japan’s most important machine tool show. The 2008 show reinforced the trends observed at the International Manufacturing Technology Show (IMTS) that took place in Chicago two months earlier. Along with a review of the show, this article summarizes editorial visits to two new machine tool factories. The report shows that Japan continues to be a dynamic force in machine design and construction.

Read MoreRobotic Cell Locks In Time, Cost Savings

Having implemented robotic systems in the sheet metal side of its business, this Nevada-based shop wanted to obtain similar automation systems for its CNC machining operations. The Fanuc JobShop Cell from Methods Machine Tools has reduced both costs and cycle times on one of the shop’s most important jobs.

Read MoreComplementary Technologies Make MQL More Accessible

An add-on system for minimum quantity lubrication (MQL) combines an external pump with repeatable control over nozzle position.

Read More