Software Supports Cell-Based Production Process

Implementing advanced manufacturing cells can help a shop improve productivity, but the cells themselves may be only part of the solution. That’s the case at Wilcox Industries, which combined advanced manufacturing capabilities of automated machining with the flexibility of Mastercam CAD/CAM software to keep up with continuing growth.

Share

Success for any given shop often depends on its ability to find a niche or set itself apart from competitors. Some find, however, that this is only the first step. Keeping technology and processes up to date can be critical in dealing with the demands of increased business. This was the case at the Wilcox Industries manufacturing plant in Newington, New Hampshire, a shop that has managed to keep up with rapid growth by implementing advanced manufacturing cells. But the cells alone aren’t the only key to the company’s success—they are supported by a flexible CAD/CAM system that has helped Wilcox produce a much higher volume of work than anyone at the shop could have anticipated.

Wilcox’s business began to evolve in 1992. That’s when the company moved away from its traditional aerospace job shop work to focus on manufacturing products of its own design for special operations personnel and first responders. Since then, it has generated 23 patents for weapon laser designators, weapon optic mounts, trajectory sights, friend/foe systems, hybrid life-support systems and other such equipment used by the U.S. military as well as state and local law enforcement agencies.

Customers appreciated the company’s product offering, and rising demand led the shop to build a new 65,000-square-foot plant and a subsequent 55,000-square-foot addition. Growth continues to this day, as the company has doubled its sales volume in each of the past 2 years. At last count, the shop produces 40 different products and manufactures 6,500 different parts to support its assembly operations.

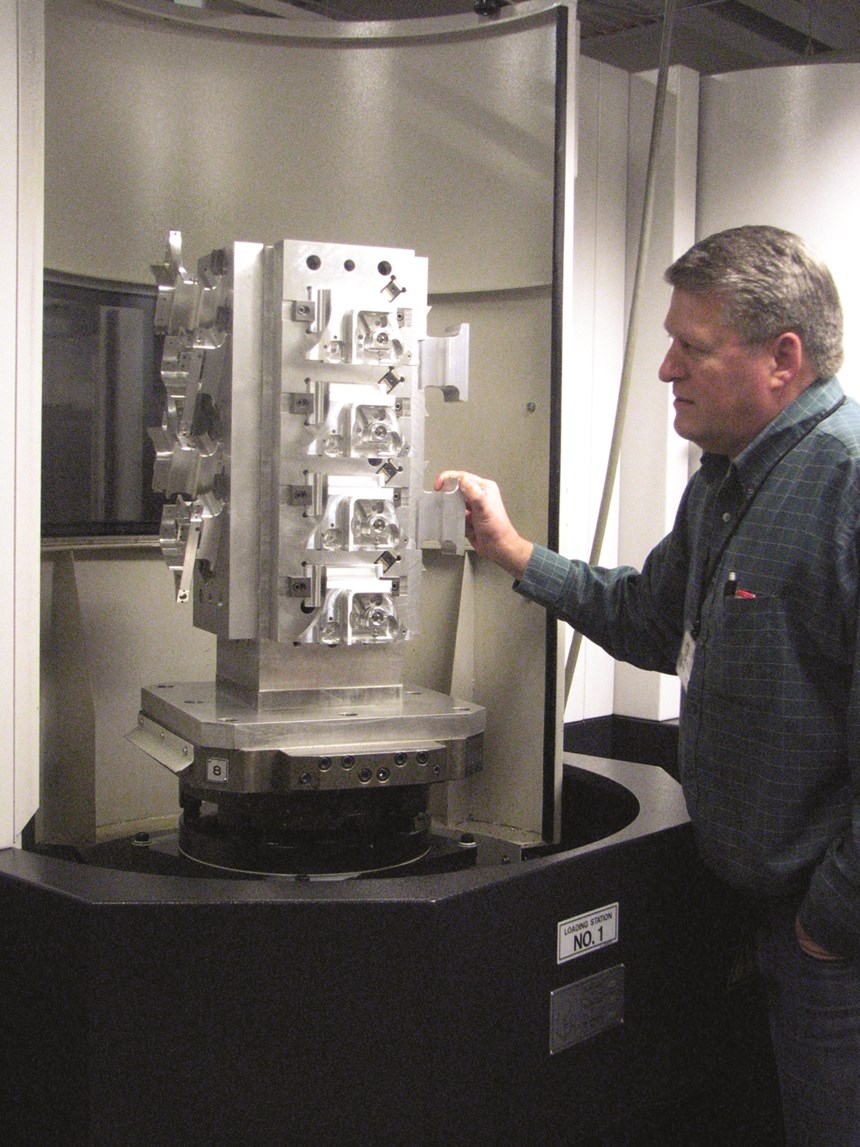

Wilcox’s new machining cells consist of three PFH-4800 HMCs from Mazak (Florence, Kentucky) equipped with dual-tier Palletech pallet changer systems and tombstone fixturing. In addition to 188 tombstone positions, the machines are supported by a library of 160 tools that allows the shop to set up parts of widely differing geometries for unattended manufacturing. These workcells played a large role in ramping up production for the rapidly growing number of technically sophisticated, low-volume products. In fact, the cells account for a 50-percent increase in the company’s manufacturing capacity, says Dan Derosiers, vice president of manufacturing.

However, the shop also needed a CAM system to keep up with the rapid pace of product development and to support the automated and frequently unattended machine cells. It has come to rely on four seats of Mastercam X from CNC Software (Tolland, Connecticut). One of the most important benefits derived from the CAD/CAM software is the ability to handle a large increase in prototyping projects. Programs created in Mastercam run right the first time, the company says, helping to avoid machine crashes that can shut down production during nightly "lights-out" manufacturing sessions. "We do a tremendous amount of prototyping, and Mastercam allows us to keep up with the high demand and turnover rate on our projects," says senior programmer Phil Lord.

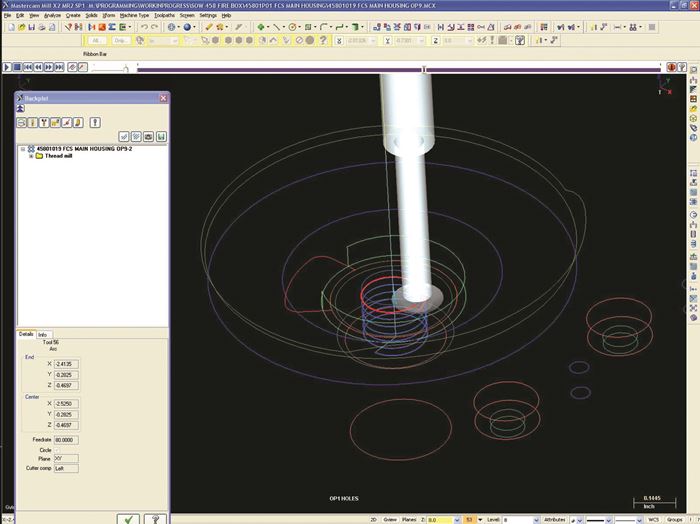

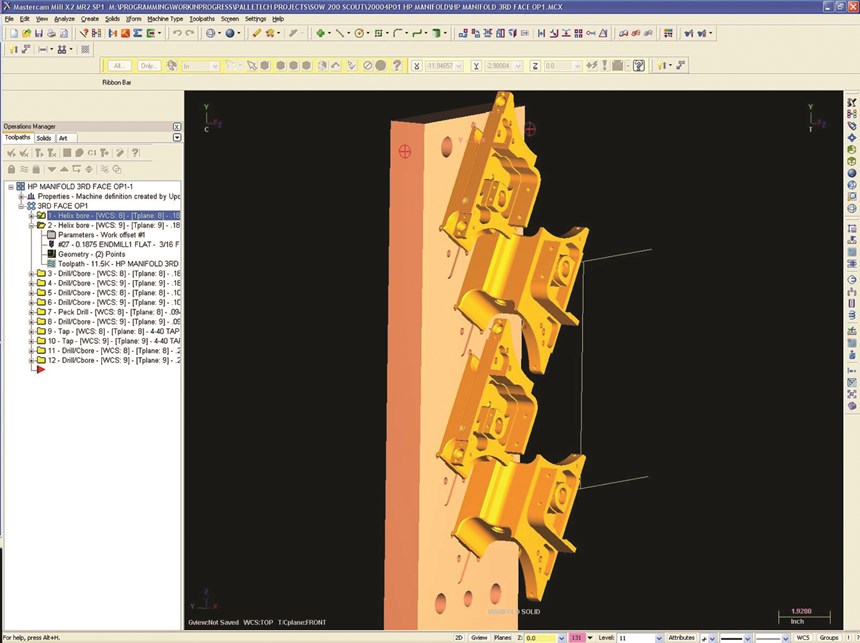

Prototypes are designed in the engineering department using Autodesk Inventor. IPT files can be imported seamlessly into Mastercam’s solids module, where tool paths and tool transitions are created. Wilcox programmers rely on the software’s verification tool to ensure that everything is right with the CNC program. This feature uses the tool paths generated in CAM to automatically create a 3D rendering of the part in question. Colored areas on the rendering indicate where too much or too little stock has been removed so that the program can be quickly fine-tuned before making the first piece.

Mr. Lord says the ability to rely on CNC posts running right the first time improves productivity by skipping redundant steps. "For instance, our workflow may call for six new pieces to be set up on one side of a tombstone for efficient manufacturing," he explains. "To make sure we are doing what the job calls for, we may make the first piece on the fixture. Then, once we have it proved out, we transform our tool paths for all six portions and go for it all."

Wilcox’s programmers lean on a variety of other Mastercam capabilities. According to the company, the software’s most beneficial features are associativity, toolpath optimization, tool library management, design assistance and export/import of operations.

All Mastercam tool paths are associative. That is, if parameters are adjusted in one part of the program, the CAD system automatically reads through the entire code set to make changes in other parts accordingly. Mr. Lord says company programmers benefit from this associative behavior on a daily basis. For example, if a solid model undergoes a major design change, Mastercam allows the company to merge the new solid with the old and then quickly regenerate the program with only minor adjustments where tool paths need to be joined.

The software’s toolpath optimization capability also helps the company keep operations efficient. While the spindles on most of the shop’s CNCs are not considered high speed, Mastercam’s high speed machining tool paths still provide more efficient operation on the conventional spindles.

Additionally, many of the tools used in the machining centers’ 160-tool library were designed in Mastercam. Thus, programmers always have the right tool for the operation at hand. The ability to bring tool drawings right into the programming environment also contributes to accurate toolpath verification for better process control.

While most design work is done in the engineering department with Inventor, there are times when Mr. Lord uses Mastercam to help design unique angles or other difficult features. This helps better integrate designs with the capabilities of the manufacturing equipment.

Finally, Mastercam allows programmers to export operations they create to a library. That way, they can easily import the operations for a similar job to reduce programming time. Mr. Lord cites a mirrored part as an example. By importing the operations used in making its predecessor, the software automatically records the appropriate tool setting and machine parameters to eliminate a substantial amount of work.

To accommodate its ongoing growth, Wilcox has ordered another Palletech machining center and is planning another plant expansion. The company is also looking for ways to integrate additional manufacturing processes with Mastercam. This could include using the software to program SLR prototypes or to further improve the productivity of the company’s Integrex multi-spindle machines.

In the meantime, the shop continues to use Mastercam to program a succession of difficult parts much faster than was possible in the past. "I’m doing one now that ties together seven different operations—both 2D and 3D work," Mr. Lord says. "It’s a difficult part, but we will have the prototype manufactured in just a day or two."

Related Content

Fryer Offers Compact HMC for Small-Lot Machining

The Fryer HR-40 features a built-in 24" rotary table for multi-sided machining.

Read MoreWeingärtner Maschinenbau HMC Provides Stable Machining

The MPMC features a wide base, optimized guide ratio and configuration of the guideways to provide stability and prevent vibration during operation, even under extreme cutting conditions.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)