Grinding Turbine Rotors Has Advantages

For many aerospace components, grinding systems achieve greater productivity than milling and broaching on today’s lighter, tougher, harder materials. Tests performed at Saint-Gobain Abrasives’ Higgins Grinding Technology Center in Worcester, Massachusetts, showed that along with the latest abrasive and bonding technologies, the systems approach produced remarkable results when applied to grinding turbine rotor root-form slots.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Today’s lighter, tougher, harder alloys and ceramics are difficult to machine using traditional methods such as milling and broaching. In addition, requirements for precise dimensional tolerances (to microns), intricate workpiece geometries and super-fine finishes are pushing manufacturers of aerospace and other precision components to CNC grinding as the best method for finishing their products. Another motivation for this push is that when broaching is used as the primary machining operation, the secondary deburring operation often takes longer than the broaching. Broaching can also result in shorter fatigue life for certain components, an especially important consideration in the aerospace industry.

How can a shop use grinding to meet all of the above requirements? The answer lies in following the "systems approach." That is, rather than adopting a piecemeal approach to the grinding process, manufacturers should view individual elements such as the abrasive tool, operating parameters and the machine itself as interrelated parts of a complete system.

Tests performed at Saint-Gobain Abrasives’ Higgins Grinding Technology Center in Worcester, Massachusetts, showed that along with the latest abrasive and bonding technologies, the systems approach produced remarkable results when applied to grinding turbine rotor root-form slots. With a grinding system in place, setup time was about one-twentieth and cycle times approximately one-third of what they were with broaching. The occurrence of burrs went down by half, significantly lowering the rejection rate, while tooling costs decreased by as much as 50 percent.

A Trend Back To Grinding

In recent years, there has been an effort to replace grinding with hard turning and high speed machining—with reasonable success. However, for some part shapes and materials, these processes have proven to be uneconomical because of high tool wear—which makes holding size difficult—and high tooling costs. Subsequent damage to the part surface resulting from dull tools affects product reliability. Several manufacturers have encountered these drawbacks of hard machining and are reverting to grinding to meet specs.

Other manufacturers, particularly those in the aerospace industry, continue to steadily move away from commonly used grades of steel in favor of exotic alloys, composite materials and ceramics. Nickel, titanium, powdered metals, stainless steels and micro-grain, high-strength alloys are considered difficult to machine because of the very properties that make them desirable for their chosen applications. However, thanks to a new understanding of how to manage the total grinding system and advances in the technology itself, grinding can bring these materials to closer tolerances more quickly and reliably than other technologies while maintaining excellent surface integrity.

Because many of these materials are used in jet engines, any improvement in surface integrity improves engine reliability and reduces maintenance costs. Meanwhile, new materials and methods of manufacturing are also required in the automotive, bearing, gear, medical component and tooling industries to meet demand for improved performance and reliability.

Grinding typically produces better finishes and holds closer tolerances than other chip-making processes. Another benefit, largely overlooked by some, is that because grinding removes smaller chips (but more of them), it produces smaller burrs. This is a distinct advantage when machining high-strength, ductile materials with complex geometry. In some of these processes, deburring can cost as much as or more than the machining operation, and the smaller burr produced by grinding can significantly reduce deburring costs.

Getting To The Root Of The Problem

In recent years, Saint-Gobain Abrasives has been working with the aero-turbine industry to improve the manufacturing process for cutting root form slots in turbine rotors. Typically, producers of turbine rotors use a combination of milling and broaching to cut these slots. Three factors made it clear that a new process was necessary:

1. Thanks to demand for reduced weight-to-thrust ratio and improved fuel economy, new turbine designs specify new super alloys that are even more difficult to machine than those currently used for the rotors.

2. As these new engines enter production, new and costly broaching tools are required. Because of their complexity and a limited base of capable suppliers, lead times for these tools are long. Moreover, broaches do not last as long with the newer materials and need more frequent resharpening.

3. Many broaching machines are getting old and will need replacement or rebuilding in the near future.

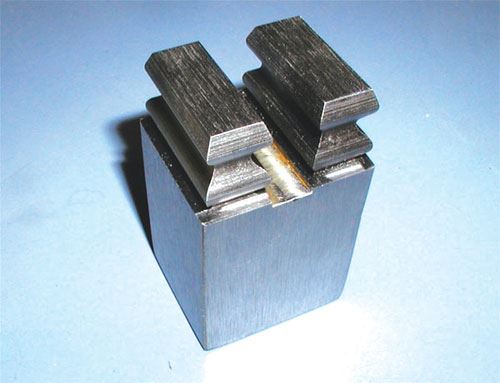

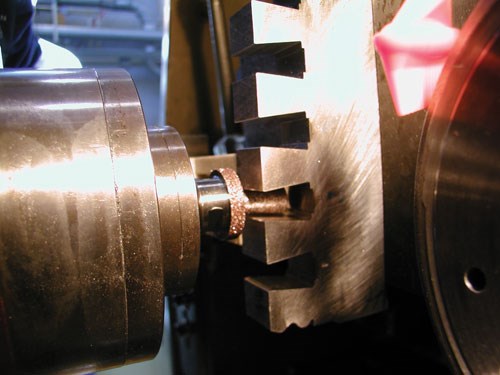

To replace broaching in cutting these slots, St. Gobain Abrasives has been developing and testing a grinding process that utilizes electroplated cubic boron nitride (CBN) abrasive tools. CBN was chosen because its high thermal conductivity and wear resistance significantly prolong tool life when grinding nickel alloys. A CNC machine with high loop stiffness was modified to simulate the eventual production process. By measuring normal and tangential forces, power consumption and other factors, researchers studied the performance of various abrasive tools under different machining parameters. Different coolant formulations and application techniques were also tested. Analyzing results and redesigning the abrasive tools eventually led to a final design that was ready for production testing.

These tests demonstrated that the CBN grinding process could enable material removal rates of more than 20 cubic inches per minute on a straight-sided slot measuring 1 inch wide and ½ inch deep in 100CR6 steel. Removal rates of more than 10 cubic inches per minute could be achieved in 4340 steel. In M2 tool steel (Rc64) and Inconel 718, removal rates could exceed 5 cubic inches and 2 cubic inches, respectively. In other tests that involved using mounted point tools for operations similar to side or flank milling at a depth of 7/8 inch, material removal rates of 0.08 cubic inches were achieved in 100CR6, 1018, 4340 and Inconel 718.

These results indicate that substituting the CBN grinding process for broaching can reduce setup time by 95 percent and cycle time by 66 percent. Grinding also produces less residual stress, improving the fatigue life of turbine rotors and reducing rejection rates by as much as 50 percent. An added benefit can be a significant reduction in the time and cost of deburring and finishing the rotors. Finally, the process can decrease tooling costs by as much as 80 percent.

St. Gobain estimates that this development can save a manufacturer as much as several million dollars per year, depending on production volumes. However, achieving these results does require capital investments to convert production to the new grinding process. This conversion can be justified by using the systems approach to examine total costs because these types of results are only possible when the grinding process is looked at as a complete system. Each element of the system must be designed for the given material to achieve the required economic and technical requirements.

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)