The Million-Dollar Job

A shop specializing in large parts describes the most expensive single order it ever shipped.

Share

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreTech-Max Machine was not originally founded to be a shop specializing in large parts, but over time that is what the shop became. President Richard Malek and Vice President Ted Morawa say the trend in their shop’s machine purchases over the years has been steadily upward in terms of size. Each new machine has tended to be larger than machines that preceded it. Today, all but one of the machining centers in this shop in Itasca, Ill., has at least 40 inches of X-axis travel, while half of those have 50 to 80 inches, and the largest is a boring mill with 120 inches in X. Mr. Malek says “big” is where he wants his company to be.

There are multiple reasons for this. Shops making small or mid-size parts face plenty of competition, he says, but as long as Tech-Max can keep its machine travels up in the range that few other shops can match, it gets to enjoy a variety of benefits. In his experience, those benefits include:

1. Diversification. To distinguish themselves, many shops specialize in the needs of a particular industry. Large-part machining, by contrast, is a specialty needed by many industries. Tech-Max’s customers come from sectors such as oil and gas, conventional power generation, nuclear power generation, food processing and defense, among others. Mr. Malek says business needs to decline sharply within two unrelated sectors before his own business is affected.

2. Imagination. Large-scale parts often are also unusual parts that pose unusual challenges. In addition, speed is rarely an issue, since physics itself prevents large-part manufacturing from being rapid manufacturing. The challenge instead is typically to make the massive and unusual part to print without error, and Tech-Max’s team generally has the freedom with each new job to imagine the best way to achieve that goal.

3. Selectivity. This shop has little enough competition and ample enough prospects that it can choose which projects it wants to take on, and which companies it wants to do business with. For example, the shop chose to take on the project described on the following pages, an unusual job that extended benefit number 1 to yet another sector (electrical utilities) while challenging the shop to fully apply benefit number 2.

The work was completed in 2011. However, when Mr. Malek recently told me the story of this job—the most expensive order his company has ever shipped, with nearly $1 million dollars of work sent to the customer in one shipment—I decided it was a story I wanted to share and preserve. The photos to follow, which were taken by the shop, detail one of the more distinctive sets of parts I’ve known a job shop to run, and also illustrate an extreme case of the type of opportunity that sometimes comes along because of the shop’s large-part capabilities. Here was that job:

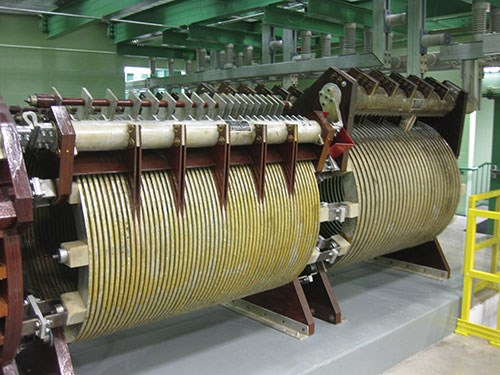

1. Replacement Coils

Tech-Max was asked to replace a set of coils, including the two seen above, which were used to develop very large and precisely controlled electrical currents in order to test equipment used in electrical power grids. Originally made in the 1960s, these coils were beginning to crack. The coils came in two sizes: 59 inches long with 27 turns and 65.5 inches long with 55 turns. “Giant aluminum Slinkies,” Mr. Malek calls them.

No one knew the right way to produce them. The Austrian manufacturer that originally made them was no longer in business. Tech-Max was left to figure out the production method on its own. Initially, the shop thought to make the coils by machining half-circular segments and welding them end to end. However, the team abandoned this idea because the original coils showed no evidence of such welding. Each coil had apparently been made in a single piece. For the replacement coils to perform like the originals, it seemed that each of the new coils ought to be made in a single piece as well.

Compounding the difficulty, the new parts had to be made without the existing parts being damaged or taken out of service before the replacements were ready. That left Tech-Max without a way to learn definitively which alloy of aluminum the coils were made of. Was it 6061-T6 or some other? Mr. Malek did research to try to answer this question. As a practical matter, he says, 6061-T6 likely was the only aluminum alloy available for a job like this in the 1960s. This choice of material therefore seemed a good bet.

2. Forging

The cylindrical aluminum forgings for the coils came from Scot Forge of Spring Grove, Ill. Mr. Malek says having a relationship with a company producing large forgings has proven invaluable, to the point that maintaining the trust of this company is probably the shop’s most important marketing investment. Large forgings often need machining, and Scot Forge routinely recommends Tech-Max for this work. Mr. Malek was therefore happy for the chance to get Scot Forge involved in the project.

3. OD Turning

Tech-Max’s vertical turret lathe sees a lot of use. The machine is a Giddings & Lewis VTL rebuilt in 2009. It features an 84-inch swing diameter, 72-inch diameter travel and 80 inches of travel vertically. The machine is seen here performing the first CNC machining operation on one of the coils.

4. Groove Milling

A helical milling path produced the individual turns of each coil. Programming this path wrong—say, getting the slope of the helix in error by just enough to produce the wrong number of turns—would have been an unfixable error that would have scrapped the entire forging. The shop therefore employed a simple but effective verification method to check the path: It ran the program one time with a Sharpie marker in the spindle in place of the tool. The black lines from the Sharpie cycle are still visible in the photo below.

Another photo, the thumbnail image near the start of this article, shows a later pass on this same machine in which the milled slot is being cut even deeper. This milling never went all the way through. Instead, to keep the part intact and stable, the inside diameter was kept whole until the very end, with an ID turning pass removing the last of the material. One great unknown throughout the job was the question of what would happen when this material was cut away. Would the coils immediately spring out of shape because of relieved internal stresses? (Fortunately, they did not.)

5. Faster Groove Milling

The boring mill’s 2,000-rpm spindle was too slow to mill the aluminum effectively. Tool failure from built-up edge was a frequent problem. For the larger coils that had considerably more turns, the shop invented a speed-increasing attachment for its spindle. Through trial and error (the error mostly related to keeping the gearbox sufficiently cool), the shop was able to engineer an attachment that was reliably capable of increasing the machine’s speed by a factor of three. For safety, the shop generally ran at half of this possible speed, so the larger coils were machined at 3,000 rpm instead of the machine’s own upper speed limit.

6. Assembly

Tech-Max is not just a machine shop but also a machine builder. Its customers in the food processing industry, for example, are often designers of custom machinery, and they need more than just CNC machining services. These coils, too, required work in addition to machining, and that additional work deserves to be noted because it was a finicky manual operation. Insulator sections that had been cut to custom size and shape via waterjet were precisely positioned and glued in place between the turns all along the coil and throughout the length of each part. These sections are the red material visible in the spaces between all of the turns.

7. Shipping

This project was seemingly the ultimate case of a one-time job, never to be repeated. Its uniqueness and cost were such that Tech-Max was careful to secure important concessions from the customer. The shop committed that it would make the parts to print, but it made no guarantees regarding the performance of the parts once they were installed in place of the existing coils. After all, the belief that the prints accurately described the original coils in every detail that mattered to the coils’ performance remained just a guess. Also, the customer accepted delivery of the parts not when they arrived, but instead when they were loaded onto trucks at Tech-Max. It would be the customer’s loss if somehow this million-dollar order was damaged in transit.In the end, neither of these concessions proved to be necessary. The parts arrived unharmed, and when they were installed, the new coils performed precisely as the old ones had. Mr. Malek and the Tech-Max team had guessed correctly in every choice they made in engineering these coils—or at least correctly enough that the new coils were functionally indistinguishable from the originals. He says he only wishes he can be there to explain his shop’s work 50 years or so from now, when these new coils themselves might need to be replaced.

8. Never Boring (Even on a Boring Mill)

The chance to take on work as interesting as this job is one of the genuine rewards of cultivating the relatively rare specialty of machining large parts, Mr. Malek says. He is seen here standing beside a much more recent order, a batch of parts that is every bit as interesting in its own right. Though these stainless steel pieces were much simpler to produce than the coils, their story is historic. He says these are lids to containment vessels that will hold spent rods from the cleanup of the Chernobyl nuclear power plant.

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)