Taking Titanium Seriously

Does titanium justify a machine that is engineered for this metal?

Share

If you machine titanium, particularly large titanium components, then there is good reason to consider a machine tool that was designed for this metal.

An example of a machine tool supplier offering machines such as this is SNK America. Indeed, in the company’s new Chicago-area tech center, two of the four large-travel machine tools currently being used to prove out customer processes are machines that were engineered toward the purpose of milling titanium aggressively. However, company National Sales Manager Mike McGuire says the main obstacle to the adoption of these machines is simple to spot and easy to understand.

“These machines are not inexpensive,” he says.

But then, neither is titanium. This metal is costly. Meanwhile, partly because of the expense of the material and partly because of the nature of the parts, large titanium components tend to be high-value jobs offering the potential for lucrative profit margins when they are made productively. Perhaps more than any other metal, titanium promises a high return on any investment that increases metal removal rate to raise productivity.

Many shops don’t see this because of the way they have long been accustomed to running this metal. Many have migrated gradually from machining titanium once in a while to now machining it routinely. Despite this development, they continue to machine the metal as best they can on machine tools suited to less challenging material. The result is what Mr. McGuire calls “nibbling”—taking light depths of cut and carefully chosen tool paths to try to whittle a titanium workpiece with a passable level of productivity. It’s often assumed that this is the way titanium has to be machined, he says. But nibbling isn’t necessary. A straight slot in titanium can be machined with deep passes, just as it is in other metals. Part of the way a titanium-appropriate machine tool helps productivity is by allowing the simplest machining options to be the most efficient ones.

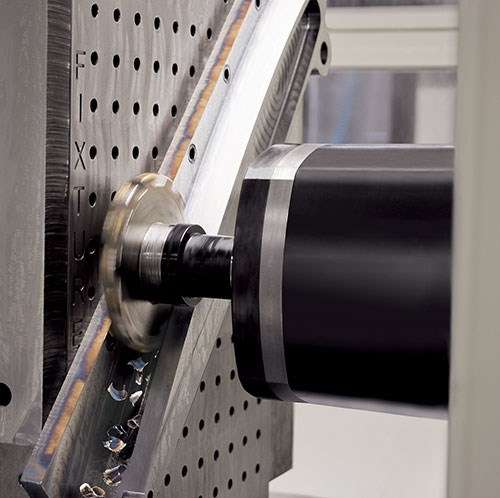

Hold Down Heat

The video and corresponding photos on this page illustrates that point. The workpiece shown, a representation of an aircraft flap track, features a 1-inch-thick slot. On a horizontal machining center engineered for titanium, the slot was machined quickly and straightforwardly using an 8-inch diameter side milling cutter with a 0.25-inch corner radius at a depth of cut of 2 inches. The video, though it shows the cut in steel for the sake of running without coolant for visibility, shows the pace of this cutting in the titanium process.

The machine making this cut is an HN80D box-way horizontal machining center from Niigata (an SNK Machine Tool Group company). However, this “Ti” version of the machine has features for heavy cutting that go beyond the box ways. The titanium version of the machining center includes a high-torque CAT 50 Big Plus spindle and high-torque axis motors. The machine also features 50 percent more clamping force on the table compared to the standard for this machine, as well as increased clamping force on the toolholder.

Rigidity is doubly important in machining titanium. In titanium, the rigidity of the process is important not just because of the tensile strength of the metal, but also because of the risk of heat. Titanium is a poor heat conductor that tends to produce heat build-up in the cutting zone during machining. This is the principal challenge of cutting this metal. Holding this heat effect below the level at which it impairs the cut involves various factors, including not only high pressure and volume of coolant, but also a sharp cutting edge that keeps the power demand of the cut as low as possible. This sharpness is particularly sensitive to vibration. Vibration in the cut is likely to dull the edge, leading to increased power and heat in the cut, leading in turn to a process that no longer mills titanium effectively. Therefore, in titanium, the machine and the process are engineered for high rigidity in part to keep the temperature down.

High Mix Machining

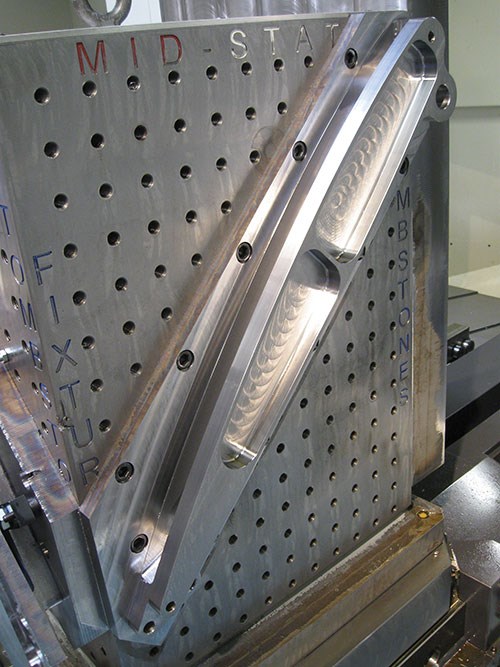

An example of a machine for even larger and more intricate titanium parts is SNK’s HPS 120A five-axis profiler. This machine also features box ways, high-thrust servo motors and a high-torque spindle. The spindle is mounted in a full contouring head permitting a 180-degree range of motion in the A axis and 360 degrees in C.

Being able to take deep cuts in titanium through these large angular ranges of motion changes the processing strategy for many parts that migrate onto a machine such as this. Long titanium structures are often machined on gantry mills, which often have much less rotary-axis range. For extreme angles, the parts therefore require multiple setups. The profiler saves time not just with a high metal removal rate, but by combining previously separate operations into a single cycle.

The machine also has a horizontal configuration—another feature that helps with the efficiency of the cut. Chips fall away from the cut, reducing the danger that the process will lose efficiency or the tool will lose sharpness as a result of re-cutting chips.

For part loading, however, the work table pivots to lie down. The machine can therefore be loaded and unloaded quickly, and even serviced by a flexible system such as a pallet shuttle. This fact, combined with the machine’s ability to produce the part in a single cycle, allows it to make large parts efficiently in small quantities. Mr. McGuire says at least one major user of this machine type committed to it with a view toward how the future demand for titanium aircraft parts is likely to favor this very advantage. In the years to come, when backlogs for aircraft orders have been worked off, production activity is liable to shift toward being lower volume and higher mix. If that happens, then accommodating this type of demand is another way in which a machine designed for the particular needs of titanium might pay dividends.

Read Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More