A Modular Clamping System for Bulky Parts

Here’s one fixturing alternative for clamping large workpieces such as mold and fracking components.

Share

Takumi USA

Featured Content

View More

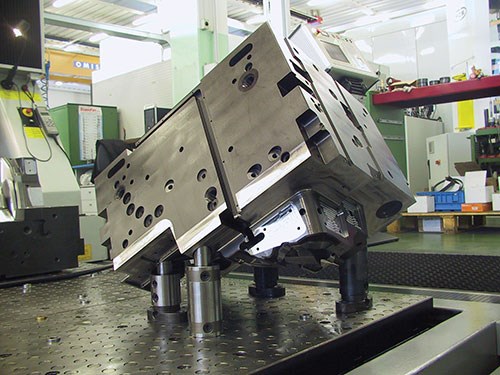

The FCS modular clamping system was designed to minimize setup times, enable machines to access five sides of a fixtured part and provide highly repeatable positioning so parts can be removed and accurately refixtured as needed.

FCS Moulds, now Elmann S.R.L.U., is an Italian moldmaker that sought to develop a standard means of fixturing mold components that would minimize setup times, enable its machines to access five sides of a fixtured part, and provide highly repeatable positioning so parts could be removed and accurately refixtured at the same zero reference points as needed. Ultimately, its goal was to increase its machines’ spindle utilization so it could be more competitive with foreign moldmakers.

The solution it developed eventually turned into a product line that’s well-suited for clamping big, bulky components. Learn how you might benefit from it.

Related Content

-

How a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

-

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

-

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.