Holemaking

Tool Blanks In Carbide, PCD, PCBN(2)

Iljin Diamond’s Epsilon Tungsten Carbide rods and blanks are used to produce end mills, drills and reamers as well as micro drill and router bits. Available sizes range from 1.2 to 32 mm in diameter with 320-mm standard, unground length. Options include straight or helical coolant holes and pre-forming. Manufacture

Read MoreExit-Side Drill Penetration Without Delamination

Slow-motion video shows the effect of a micograin tool coating in drilling CFRP.

WatchDrill And Chamfer In A Single Operation

The Vex-S drilling and chamfering tool combines the company’s Snap chamfering system with the Vex twist drill in order to drill and front/back chamfer a through-hole in a single operation. The combination tool offers a solid carbide, replaceable twist drill tip with the company’s Vex cutting geometry, which is desi

Read MoreLaser Cutter Taps Into “Done-in-One” Fabrication

Multitasking machines offer a number of advantages, including reducing multiple setups that require manual material handling and refixturing. However, many fabricators still use multiple operations on separate machines to process tube and pipe components. Secondary operations such as tapping are especially prob

Read MorePrecision Boring In Precision ER Collet Holders

In the past 20 years or so, the ER-style collet holder has become a de facto standard for retaining round-shank type tooling in milling and machining center applications. A precision boring system can now be included in the range of tooling compatible with precision ER-style collet systems. The ER collet featu

Read MoreDrill Deletes Delamination In CFRP

Composites are becoming increasingly common in aerospace applications, and machining new materials can be a challenge for shops used to cutting metal. One such substance, carbon fiber-reinforced plastic (CFRP), can be difficult to drill because tools often “push” through the material rather than executing a cle

Read MoreMore Than Big Machines

This shop specializes in very large components such as rotor hubs and support bases for wind turbines. Its lineup of large horizontal boring mills can handle parts weighing 40,000 pounds and 12 feet on a side. However, the shop’s success also lies in other manufacturing resources and strategies. These include material handling equipment, customized tooling, special fixtures and wireless, portable measuring systems.

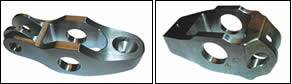

Read MoreTurning Is Optional

The part requires only milling and drilling, but it is still run on a lathe. Except for the cutoff tool, all of the turret positions on this lathe hold rotating tools. In other words, turning is not essential for using a lathe effectively. This application illustrates the productive possibilities of a modern turn-mill machine.

Read MoreGear Manufacturer Cuts Costs By Reclaiming Used Tools

This gear manufacturer needed to reduce high costs resulting from replacing dull drill bits or sending them out for sharpening. With the XT3000 Xpandable tool sharpener from Darex, the shop has done just that. In addition, the device allows the company to custom-sharpen drills for specific jobs.

Read More

.png;maxWidth=300;quality=90)