Holemaking

Reducing Thrust Loads During Rigid Tapping

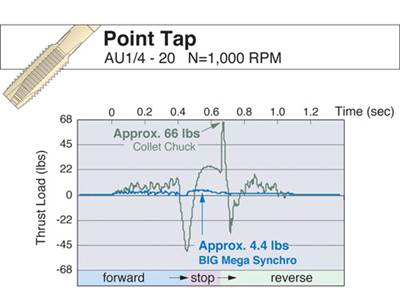

Some amount of synchronization error is inevitable with rigid tapping. By allowing just a slight amount of axial movement to compensate for synchronous errors, this tapping holder is said to reduce thrust load by as much as 90 percent.

Read MoreBe Strategic With Your Holemaking Options

Just as there are a great many types of holes to be produced in today’s complex workpieces, there are a great many types of holemaking processes. Finding the right cutting tool for each holemaking application is a matter of asking the right questions and getting good answers from a cutting tool supplier.

Read MoreCoolant And Center-Drilling Considerations For Machining Small Holes

Through-spindle coolant is good if you can get it, but the spot drilling might not be necessary. Try a pilot hole instead?

Read MoreHMC Combined With A Boring Mill

Absolute Machine Tools’ You Ji HMC-1000BP combines boring mill features with a 77,000-lb, moving saddle design HMC. A box-in-box structure confines spindle movement inside the column casting, which reduces moving mass and to allow faster acceleration and rapid rates.

Read MoreHow Do You Machine a 30:1 Hole in Stainless Without the Drill Wandering?

An expert in micromachining says one answer is to check various aspects of the drilling process. Another answer is not to use a drill at all.

Read MoreDrilling Solutions Improve Tool Life, Cut Cycle Times

Interruptions due to worn or failed tools can be especially detrimental to productivity, especially on parts with lengthy cycle times. At a manufacturer of large commercial heat exchangers, many of which require drilling of hundreds of holes, the improved tool life of Precision Dormer’s Hydra and CDX-Inox drills led to significant cost and cycle time savings.

Read MoreA Deeply Holistic Approach

In its effort to streamline every step of the mold building process, this company has upgraded its deep-hole drilling capability with a new six-axis machine. A rotary table with magnetic workholding enhances this machine’s flexibility.

Read MoreUniversal Milling Machine For Complex Applications

Suited for vertical milling, drilling and tapping, Knuth Machine Tools USA’s VHF 3 universal milling machine also includes a horizontal arbor for horizontal milling, slotting and keyway cutting. The machine is useful for mechanic workshops, production, training, single-part manufacturing and prototyping.

Read MoreModular Drill Diameter Range Expands

The Ken TIP modular drill system from Kennametal features various solid-steel bodies (3 × D, 5 × D and 8 × D, among others) and replaceable drill points for precision hole-making in steel. The modular design allows users to keep the drill bodies in a machine or holder and replace drill points as needed. Running at speeds comparable to those of solid carbide drills, the system offers high metal removal rates compared to common modular drills and reduces setup times, the company says.

Read MoreModular Drills Combine Benefits Of Indexable Tools

Kennametal says its KSEM Plus modular drills combine the high feed rates and length/diameter capabilities of modular drills with the high speed and low consumable costs of indexable drills. The drills offer increased metal removal rates and productivity in various applications, including the energy market. The drill bodies accept a range of head diameters, and inserts or heads can be replaced without removing the body from the spindle.

Read More

.png;maxWidth=300;quality=90)