Holemaking

Minimizing Turning Center Cutting Tool Touch Off

Turning center cutting tools vary from one type to another. When the turret rotates a cutting tool into position, the cutting edge of a turning tool will be in a different position than the cutting edge of a boring bar, a drill or a back-turning tool.

Read MoreAerospace Shop Reduces Setups With Boring Mill

A recent survey prompted Ace Clearwater Enterprises to acquire a boring mill and implement a new MRP system. In turn, it was able to bring processes in-house and accelerate cycle times while better serving its clientele.

Read MoreOil Drill Coupling Production Gets Automated

Sponsored by Okuma. A manufacturing cell combines lathes, gantry robot and conveyor system to enable automated production of oil drill couplings.

Read MoreRepetitive Part Cutting: Improve Productivity by Learning Path Error

Significant improvements in speed and accuracy are now possible by using a CNC system that can learn and correct for its path error. Expanding the functions of learning control past specialized machines into general machining is the next step in the evolution. Now learning functions can be applied to free profile machining, drilling and tapping. The benefits of applying learning control come from its ability to correct for path and synchronous error seen in repetitive cycles. Once learning is complete reduced cycle times and increased accuracy result.

Read MoreDealing With A Spot Drill’s True Point Position

A spot drill has a 90-degree point angle, which makes it easy to calculate the depth of a hole to be spot-drilled. You simply divide the diameter of the spot-drilled hole.

Read MoreAutomotive Supplier Speeds Metal Removal With Boring Mill

In an industry where one in three shops has closed during the past 10 years, Fischer Tool and Die's business is thriving. According to the Temperance, Michigan shop, this is because its growth stems from die cast work for the automotive 'new domestics,' a term for transplants.

Read MoreSelf-Reversing Tapping Head Speeds CNC Production Job

When Prestige Precision Products (PPP), a shop in Rochester, New York, began ramping up for a recent high-production job, it made a substantial investment in new equipment dedicated to the project. Among the acquisitions were a new HMC with a pallet changer, customized tombstone fixtures for the pallets and some innovative tooling items. The part, an aluminum component for the automotive industry, had one hole to be drilled and tapped.

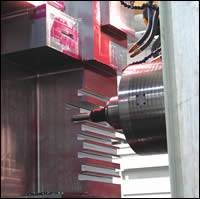

Read MoreRe-Designing The Reamer

This reaming system uses a multiple-cutting-edge, solid carbide cutting disc that can be changed as easily as an end mill's insert.

Read MoreA Few Tricks With Turning Center Canned Cycles

Most turning centers are equipped with some helpful canned cycles. Fanuc, for example, has three simple, one-pass canned cycles (G90 for turning and boring; G92 for threading; and G94 for facing).

Read More

.png;maxWidth=300;quality=90)