Holemaking

Hole-Finishing Tools Designed For Fine Surface Finishes

The company’s line of hole-finishing tools includes Burraway and Burr-Off mechanical deburring tools for controlled edge break or burr removal on both sides of holes in one pass. Shefcut precision reaming and boring tools which are designed for accurate size, fine finish and superior hole geometry are also available. Tools for burnishing include multi-roll, single-roll, and diamond burnishing tools, which are said to provide for accurate sizing, fine finishing, and work-hardening of bores and shafts in seconds.

Read MoreCobalt HSS Drill For Deep-Hole Drilling

For deep-hole drilling, the company offers the Helios 15D and 20D cobalt HSS drills. The drills can process deep holes without the use of an internal coolant supply and without pecking. The flute design improves chip evacuation, making it feasible to drill as much as 20 × D without pecking.

Read MoreTapping Holder Improves Thread Quality And Tap Life

The Mega Synchro tapping holder compensates for synchronization error during rigid tapping by reducing the thrust load to both the tap and workpiece, improving thread quality and tap life. This is facilitated through a mechanism that absorbs the pitch difference between the tap and synchronous spindle. Capable of supplying coolant through slits to the tap periphery, the holder is available in various lengths and spindle interfaces to suit any company’s needs.

Read MoreMicromachining: Drilling Is Doable

This shop drills 0.020-inch holes as part of a machining cycle that also includes full-size tools cutting full-size features.

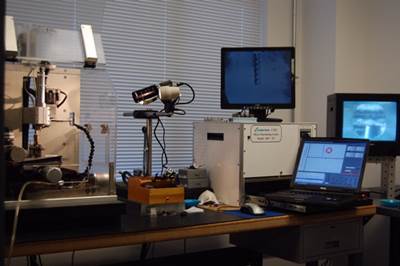

Read MoreVideo: Drilling 0.020-Inch Holes In Stainless Steel Aerospace Part

This footage on a small drilling machining also includes machining with full-size tools in the same cycle.

WatchWhere Does Diamond Make Sense In Machining Titanium?

Boeing machining experts say one application is drilling Ti-Composite stacks. PCD does well here. The group recently addressed this question submitted through our Aerospace Machining Zone.

Read MoreTools For Aerospace

Robb Jack provides solutions for difficult aerospace machining processes, including routing aluminum skins, deep pockets in aluminum, machining high-temperature alloys, routing composites and drilling holes in composites. The company also offers solutions for chatter problems, coolant issues, reach problems, steps on the part and deep, tight slots. In addition to the standard tools listed in the brochure, the company can modify designs to meet custom requirements.

Read MoreMini Boring Bars Create Tiny Holes

The company’s solid carbide mini-boring bars feature diameters ranging from 0. 015" to 0. 045", and they are fluted to retain maximum strength.

Read MoreChucks And Arbors Designed For Holding Thin-Walled Parts

The Conform-A-Chuck and Conform-A-Arbor workholding solutions are designed to adapt to an out-of-round OD or ID and securely grip that diameter to enable boring, honing, grinding or other machining operations without changing the original free-state shape of the part. These workholding solutions are suited for the machining of thin-walled parts such as automotive smog control air pump rotors, gas turbine parts, thin-wall tubing and cylinder liners for diesel engines. The Conform-A products rely upon a plastic material called Hydra-Fibre.

Read MoreFour-Axis CNC Drill Sharpener

According to the company, the XPS-16 CNC drill sharpener can reproduce complex, high-tech points found on premium HSS and carbide drills. This sharpener is designed for shops that require precision, simplicity and productivity, the company says. A collet chuck version of the auto sharpener is available.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)