Holemaking

New Boring Tool Phases Out Multiple-Pass Operation

Boring large holes often takes multiple passes that lead to lengthy cycle times. This oil industry manufacturer turned to Allied Machine and Engineering for help with one such troublesome application. A custom tool saved the shop hours on cycle time.

Read MoreAutomated Production Of Oil-Drill Couplings

A machining cell combines lathes, a robot and a conveyor system to enable automated production of precision oil-drill couplings.

Read MoreSimulation Software Enables "Lights-Out" Five-Axis Machining

Hall & Stavert has been manufacturing marine hardware for more than 65 years. The company incorporated Vericut machine-simulation software to verify NC programs and shorten turnaround time. Developed by CGTech, the solids-based software system interactively simulates the material-removal process of an NC program. The software depicts three- to five-axis milling/drilling and wire EDM operations as well as multi-axis turning and mill/turn machining.

Read MoreCircle Milling A Bolt Hole Pattern

There are times when you want to circle mill the holes on a bolt pattern. Possibly you want to rough the holes prior to finish boring.

Read MoreMeasuring Big: Lessons From The Oil Industry

In the world of oil drilling, there are some pretty big things. It's not just the rigs anchored out in the ocean that are huge: Everything that goes along with them seems to get supersized, including the need for gaging.

Read MoreDrill Cuts Cycle Time, Costs By More Than 60 Percent

This supplier of engineered gear and drive systems had problems with tool life and lengthy cycle times when drilling holes on a large drive shaft made of forged alloy steel. A new drilling system resolved these issues and exceeded the company's expectations.

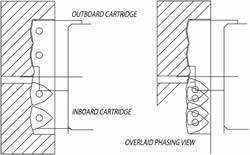

Read MoreAir-Actuated Boring Tool Offers In-Process Gaging

An air-actuated boring tool semi-finishes cylinders on the down stroke and finishes on the up stroke. In-process gaging compensates for tool wear to maintain bore accuracy.

Read MoreWhen Cold Forming Threads Makes Sense

Recent tap geometry refinement and advances in coating technologies have made the chip-less, cold-forming operation suitable for a wider range of workpiece materials.

Read MoreDual-Carbide Technology Addresses Basic Drilling Challenge

A dual-carbide-grade drill has a micro-grain carbide core blended to provide toughness to prevent chipping at the drill's point. Surrounding the core is a second carbide grade that provides hardness needed for wear resistance at the drill's outer edges.

Read More

.png;maxWidth=300;quality=90)