Holemaking

Holemaking Inserts Boost Drilling Productivity

Designed for holemaking applications, Kennametal’s Beyond insert line includes three new grades,KCPK10, KCU25 and KCU40.

Read MoreHorizontal Boring and Milling Machine

Mighty Viper offers the PBM-135 precision CNC horizontal boring and milling machine with a rotary table.

Read MoreRedesigned Website for Drill Grinding Equipment

Oliver of Adrian has launched a redesigned and expanded website that features a brief history of the company, customer testimonials and enhanced information on each machine.

Read MoreRotary Tables for High Speed Machining

The TDE-T series of rotary tables from LCM is designed to complement milling, drilling, boring, grinding and multitasking machines.

Read MoreCAM Software Features Updated Compass Technology

VISI 18, the latest CAM release from Vero USA, features updates to compass technology and drilling cycles, consolidated rapid movements and extended origin management. Compass technology now offers attribute tools that enable users to resolve conditions where general, multi-step features have to be processed in relation t the sequence of attributes associated to any step.

Read MoreWhat Don’t you Like About that Canned Cycle?

Almost all CNC users take advantage of control-based canned cycles. Even CAM systems commonly output G-code programs that contain canned cycle commands. This includes hole machining canned cycles, such as drilling, tapping, boring and more, and whatever milling cycles the machine may have. For turning centers, it includes roughing and finishing multiple repetitive cycles.

Read MoreBenchmark Your Machining Knowledge

Ryan Pohl, president of Expert Technical Training, says his company gives a 20-question, multiple-choice test to shops to evaluate their need for his firm’s “Advanced CNC Milling and Drilling” course. The questions cover important points—though not necessarily basic points—related to tools, toolholders, machine design and cutting parameters. Here is a link to the questions.

Read MoreJust don’t Call it Vibration

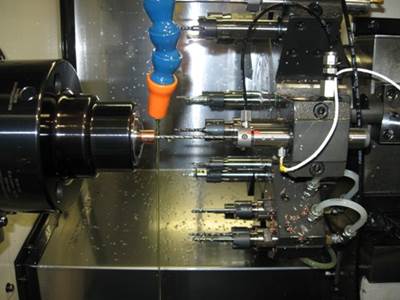

The device for rapid peck cycles holds the drill like a toolholder.

Read MoreAdvanced CNC Milling and Drilling Quiz

A provider of machine shop training offers these questions for benchmarking metalworking knowledge.

Read MoreDrilling with Modulation Delivers Pecks for Free

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

Watch

.png;maxWidth=300;quality=90)