Be Strategic With Your Holemaking Options

Just as there are a great many types of holes to be produced in today’s complex workpieces, there are a great many types of holemaking processes. Finding the right cutting tool for each holemaking application is a matter of asking the right questions and getting good answers from a cutting tool supplier.

Share

Is it a surprise that 50 to 70 percent of all tool changes are related to holemaking? Whether the type of manufacturing is mass production, a highly specialized machining shop or a mid-level supplier, hardly a part is made that does not have some kind of hole. Holes must be formed in a variety of materials, and they need to meet a number of requirements, such as level of surface finishes, quality and accuracy.

Recent tooling developments have helped to greatly reduce secondary operations. For example, high-penetration-rate solid carbide drills are often a one-hit solution for holemaking when, in the past, it was necessary to pre-drill, drill and then ream a hole to attain the desired tolerances.

Looking At The Hole Picture

In order to provide a superior holemaking solution, tool manufacturers need to ascertain the customers’ needs and wishes. Although cost per hole and hole quality are the main concerns, the variables of tool life, accuracy and stability must also be considered. Tool suppliers need to work with the customer to offer combinations that determine the best fit for their holemaking situation.

When planning a holemaking operation, certain questions must be asked to determine the optimal tooling choices.

- What is the hole diameter and depth?

- What are the tolerance requirements, level of accuracy, hole geometry and surface finish?

- How user-friendly is the tool in terms of setup time and regrinding?

- What level of productivity (feed and speed) do you need from the tool?

- How adjustable is the tool?

- What is the batch size?

- What material is being machined?

- What is the coolant delivery system on the machine?

- What is the machine spindle and taper size?

- Is there a need for a follow-up tool?

- Is a blind hole or a through-hole being drilled?

Clearing Out The Chips

Challenges abound when it comes to holemaking. High on the list is the evacuation and control of chips, making it preferable to have coolant through the spindle. Ample coolant will reduce cutting edge temperatures. With no through-coolant on the spindle, there is a depth limitation because of poor chip evacuation. It becomes necessary to drill one pass, pull out, clean, drill another pass, pull out, clean and so on, greatly reducing productivity. If chips are not evacuated from the hole, the tool will most likely break, and even with reaming, the surface will get scratched. In situations where a blind hole is being made, through-coolant must be used. Another challenge in holemaking is ensuring repeatable accuracy.

It All Begins With A Drill

Drilling is the primary method of holemaking, so the productivity or cost per hole coupled with the desired quality process determine the kind of drill a manufacturer should use. For the lowest cost, indexable drills are often the first choice. Conversely, solid carbide drills are often chosen when higher quality and accuracy are needed. However, carbide tools typically cost more. In the middle of this cost range, exchangeable head drills offer lower cost per hole compared to solid carbide drills and better hole quality than indexable.

Drills with indexable inserts are the number one choice when cost is an issue and tolerance demands are only in the IT11-IT12 range. They are good for roughing holes quickly and affordably, but unless you are simply drilling a flange or bolt hole, you will need a secondary operation. Keep in mind that indexable drilling is better for larger hole diameters (15 to 85 mm) but typically has a depth limitation of about 5×D. However, indexable drills may offer lower cycle times, especially on lathe applications. They can generate a number of hole sizes, can pass through a hole that has an uneven surface and can drill partial holes.

With exchangeable tip drills, the carbide tip can be taken off and exchanged when worn. The tool is not sent out for regrind. This helps to reduce inventory and provides consistent tool life. Exchangeable tip drills achieve better hole quality and tolerance (IT9) than an indexable drill, yet offer a lower cost per hole as compared to solid carbide. Because the range of tip drill diameters is wide, there is no need to buy a specific drill for each hole size.

These drills are best suited for the mid-range hole diameter size (10 to 25.99 mm) and still operate well at a 7×D hole depth. However, a pre-machined surface finish is recommended for this drill. High pressure coolant is also recommended to ensure good chip evacuation.

High performance solid carbide drills are the best choice for high quality, high productivity and one-hit holes. A one-piece carbide drill can handle high feeds and speeds (as much as 10 times higher than HSS drills). If the part tolerance falls within IT8, it is possible to skip a secondary finishing operation. Solid carbide drills are best for deep holes (7×D and deeper in some cases).

One benefit of solid carbide is that it can be re-ground and re-coated many times, reducing the initial upfront expense. Solid carbide drills perform best with through coolant for all but the smallest holes.

Another important consideration with a solid carbide drill is the rigidity of workpiece fixturing. Any shift in the workpiece can grab the drill and flex it, affecting both accuracy and tool life, or causing catastrophic failure of the drill.

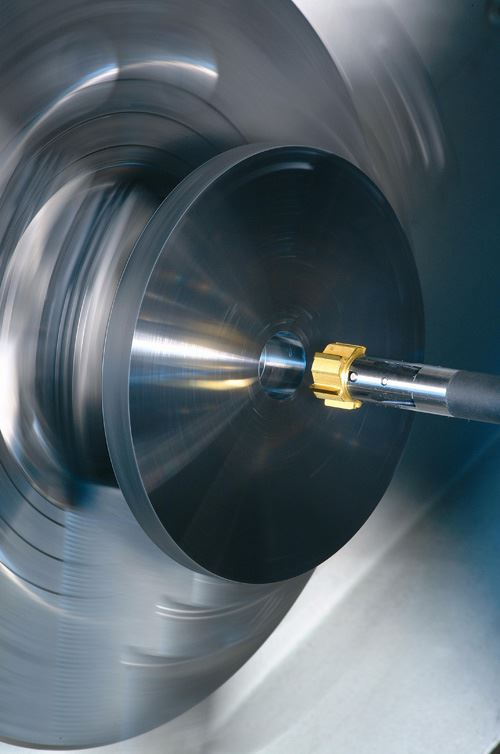

Rough Boring Has Its Place

If you want to quickly enlarge existing cast, flame-cut or drilled holes, then rough boring is an excellent choice. Rough boring heads can achieve high productivity while maintaining excellent geometrical hole precision.

Finishing Operations

Finishing of a hole can be performed by two additional operations: reaming or boring. In general, high-tolerance holes can benefit from the more precise positioning, yet slower speed of a boring operation. However, when deciding whether to ream or bore, these factors should be considered:

- What are the tolerance requirements?

- What is the quantity of the part being produced?

- What is the skill level of the operator and the shop environment?

- What are you willing to invest in tooling up front?

Reaming For Quick Bore Finishing

While reaming can be more difficult than boring, it can also be up to six times as fast, involves no presetting and provides a much lower initial investment. Reaming is especially efficient for medium to large batch sizes where high productivity and low tooling cost per hole is required.

Seco has an exchangeable head reamer, with four to six teeth, that permits extremely high feeds. This kind of tool simplifies the reaming process because it comes ground to the specified size from the factory. It can achieve diameter tolerances of IT7 because of its clamping system. The system is designed so that the coolant outlet can be set for either blind or through-hole finishing with the same head. The reamer is well-suited for medium- to high-volume production, but can also be used in small-batch production while providing low cutting forces and longer tool life than basic reamers.

For higher accuracy operations or higher volume applications, replaceable indexable insert reamers are a better choice. For example, Seco’s Precifix offers tolerances within IT6. The coolant outlet style of this tool can be manually adjusted to use the same head for either blind or through-hole applications.

Boring—From Watches To Windmills

Like reaming, boring involves the operation of enlarging an already drilled or cast hole. However, boring offers a wider range of application size, and it can handle hole diameters smaller than a millimeter or as large as several meters. It also offers flexibility, so when there is greater part variance (and typically lower part volumes), it is a better choice. The same head can be used for different sizes and tolerances, which makes boring an excellent choice for small job shops. Boring for different sizes (diameter and depth) should be chosen over reaming when a greater accuracy of the diameter (IT5 tolerance) of a hole is desired. When a hole is very rough, boring can correct a hole; reaming cannot.

If the main concern is increasing the diameter of holes productively, rough boring is ideal because it offers high chip removal. Certain boring heads can also straighten hole geometry and improve its positioning. Fine boring, on the other hand, is better if the application calls for tight tolerances, precision and a fine surface finish. However, startup costs for boring are high compared to reaming because the user must invest in a complete boring system.

Seco’s modular boring system features a strong and precise proprietary connection that is suitable for a wide range of hole diameters and depths. It consists of an array of standard interchangeable tooling components that can be assembled for boring, milling, drilling, tapping or turning applications. The system can be used both to meet special tooling requirements and for broad versatility in standard tool applications.

Also available are fine boring heads that mount axially through the center rather than radially. Seco’s line is called AxiaBore and it can handle diameters from 0.0012 inch (Nanobore) to 4.25 inches (AxiaBorePlus with MPA). AxiaBore offers 30 percent greater rigidity than previous Seco generations because of the cylinder and flange tool fixing design. This design allows for higher speeds and feeds. The indirect barrel-locking system simplifies tool setting because the set diameter is not influenced by the locking screw.

Simplifying The Tooling Process

The holemaking process can be complex, requiring multiple operations to get the correct hole concentricity and finish. Choosing one tooling supplier with an extensive offering of holemaking solutions allows customers to rely upon one source for the quality of the finished hole or even for complete metalcutting of the finished part. Considering the substantial production time devoted to making holes, choosing one source for drilling, reaming and boring products simplifies contacts, purchasing, stock and technical support. This approach can help lower the cost per hole and lead to a holemaking solution that best meets the customer’s particular goals.

Related Content

Heule Tool Enables Spot Facing of Difficult-to-Reach Areas

The manually actuated bkac spot facing tool is well suited for large boring mills and other open-air machines.

Read MoreEmuge-Franken's New Drill Geometry Optimizes Chipbreaking

PunchDrill features patent-pending geometry with a chipbreaker that produces short chips to control machining forces.

Read MoreKay Engineering's Gundrilling Machine Performs Range of Operations

Kay Engineering’s DeHoff 20144 is used to perform gundrilling, pull boring, roller burnishing and thread tapping.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)