CNC & Machine Controls

Exact Metrology Installs Large Scale CMM at Moline Facility

Exact Metrology plans to use the machine to manufacture components, parts and finished durable products that can maintain tight tolerance margins, which are essential for the use of precision machining.

Read MoreSiemens' Showcases New CNC and Digitalization Solutions

Eastec 2021: Siemens claims its new CNC system is the first to master the challenges of digital transformation in the machine tool industry.

Read MoreSix Times to Include Messages in CNC Programs

CNC machines allow users to include clarifying messages within the G code, which can be an easy way to communicate with other operators.

Read MoreVericut Update Improves Productivity and Sustainability

Vericut 9.2 includes several new features that boost manufacturing efficiency, help preserve machines and cutting tools, increase machine capacity and dramatically reduce repair and scrap costs.

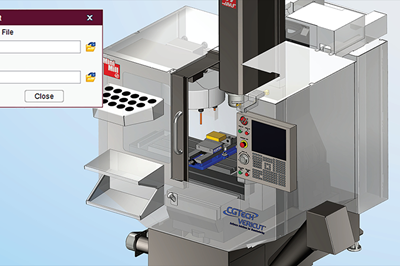

Read MoreCGTech Releases CNC Software Update

Company's Vericut software version 9.2 includes collision and performance improvements, new optimization and reporting features and more

Read MoreProbing for Setup and Lights-Out Machining — The One-Person Shop Episode #2

Automatic measurement on the machine tool speeds efficiency by day and safeguards capacity at night for a small machine shop.

WatchMeet the Automation That Makes Machine Tool Automation

A new manufacturing cell at Mazak’s North American headquarters is one part machine tool production unit and one part demonstration facility. And it’s here to provide a lesson about how automation can tackle skilled-worker shortages and supply chain issues at the same time.

Read MoreWFL Provides Basic and Advanced Process Monitoring Systems

The iControl from WFL enables users to monitor up to 16 process signals, incorporates data from external sensors, offers red and yellow limit settings and more.

Read MoreTool Libraries and Simulations in CAM Software Accelerate Cycle Times

Schupan Aluminum was able to reduce its CNC machining cycle times and perform complex five-axis work through Mastercam’s toolpaths and advanced features.

Read MoreCalling Custom Macros Through Modal Commands

While G65 does not enable users to simply and easily carry out Custom Macros in multiple locations, G66 and G66.1 provide modal solutions for doing so.

Read More

.jpg;maxWidth=300;quality=90)