Vericut Update Improves Productivity and Sustainability

Vericut 9.2 includes several new features that boost manufacturing efficiency, help preserve machines and cutting tools, increase machine capacity and dramatically reduce repair and scrap costs.

Share

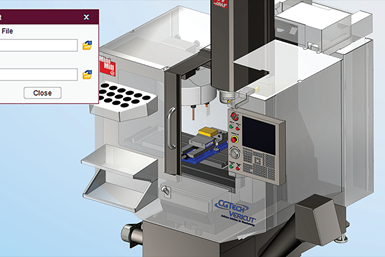

CGTech has released the latest release of Vericut software, version 9.2. Vericut CNC machine simulation, verification and optimization software simulates all types of CNC machining, additive and hybrid manufacturing processes. The software operates independently, but can also be integrated with leading CAM systems.

According to CGTech, Vericut 9.2 increases productivity and sustainability with several new features that boost manufacturing efficiency, help preserve machines and cutting tools, increase machine capacity and dramatically reduce repair and scrap costs. The company says the new version includes substantial speed increases to collision checking and overall performance, a new 3DLive interface, improved cutting tool support and reporting enhancements.

Vericut 9.2 reportedly achieves substantial speed increases for deep concave collision penetration, turning operations (especially inside diameter work on large parts) and collision checking between highly detailed models such as those having high triangle counts. The update also features new cutting tools, including conical end mills, spherical end mills and thread mills, as well as new options for hole making tools that enable users to specify how Vericut will use profile or model file cutters. Vericut checks for machining errors according to the specific tools’ capabilities and limitations. In addition, Vericut’s dimensioning tool, X-Caliper, can be used to check the dimensions of drilled or threaded holes and also to display machining information for that related hole.

CGTech’s integrated simulation optimization solution, Vericut Force, has also been updated. According to the company, Force reduces machining times, extends tool life by up to two times or more, prevents undesirable cutting conditions and improves part quality. Vericut 9.2 provides Force users with more options for setting and adjusting optimization limits, more comprehensive tooling data and greater customization options for graphs and reports.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.