CNC & Machine Controls

Juggling Mismatches in Resolution and Least Input Increment

While CNC machining and turning systems of the past only had resolutions and least input increments equal to the displayed decimal places, new systems support more precise inputs.

Read MoreCustom Macros Can Skip Holes After Replacing Broken Tools

Using “vacant” local variables enables CNC machinists to create custom macros that can target multiple types of machining work.

Read MoreMethods Moves Chicago Technical Center to Gilberts

Methods Machine Tools has moved its Chicago Technical Center from Elgin, Illinois, to Gilberts, Illinois, saying the new facility will speed up repair and installation times.

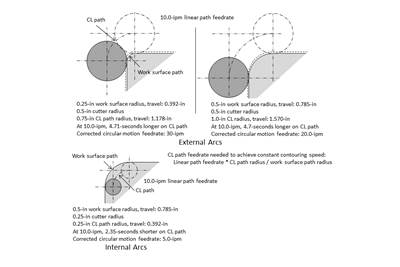

Read MoreAdjusting Feed Rate in Circular Motion Commands with G-Codes

While it is possible to calculate by hand adjustments to feed rate for circular milling operations, cutter radius compensation CNC programs streamline this process.

Read MoreReynolds Machinery Recognized As 2020 Top Hurco Distributor

Hurco has recognized Reynolds Machinery as its 2020 top distributor in unit sales — a first for Reynolds, though it has come close several times in the past.

Read MoreHow to Modify Feed Rate for Circular Motion Commands

Maintaining a constant feed rate between linear and circular milling easily leads to chatter — for most applications, increase feed rate on external arcs and decrease it for internal.

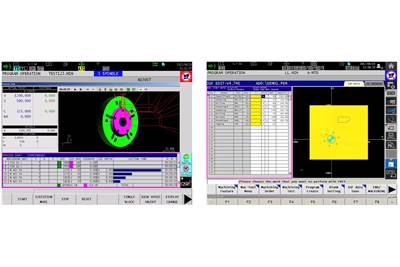

Read MoreOkuma Launches Conversational Programming on Select Machines

Okuma has launched its Advanced One Touch-Interactive Graphics Function (AOT-IGF) conversational programming software on select machines, increasing usability and speeding up setup times.

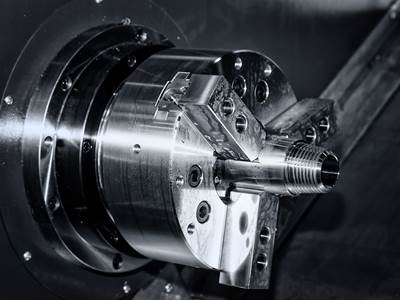

Read MoreSodick Proprietary Linear Drives Maximize Machine Accuracy

Sodick’s K4HL CNC small hole drilling machine and AL G series die-sinker EDMs feature the company’s proprietary rigid linear motor drives for increased accuracy.

Read MoreHow to Save Time When Mounting Jaws on Three-Jaw Chucks

Precisely placing jaws on three-jaw chucks for CNC turning machines is difficult, but a laser pointer and clever programming can ease the issue.

Read MoreAmerica's Cutting Edge Offers Free Online CNC Course

America’s Cutting Edge (ACE), Oak Ridge National Laboratory and IACMI — The Composites Institute, has developed a free CNC training program.

Read More

.jpg;maxWidth=300;quality=90)