CNC & Machine Controls

CNC-Related Features of Custom Macro

CNC-related features of custom macro are separated into two topics: system variables and user-defined G and M codes. This column explores both.

Read MoreComputer Programming-Related Features of Custom Macro

Custom macro is an interpreter-based language, meaning that all CNC G code and custom macro commands are executed as the CNC comes across them.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

WatchAutomation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

Watch5 Reasons Why You Should Know How to Write Custom Macros

Custom macros enhance what can be done in G-code programs, giving users the ability to code operations that were previously not possible.

Read MoreHeidenhain CNC Control Provides Customizable User Experience

Eastec 2023: The TNC7 provides virtual simulation of the machined part and work envelope.

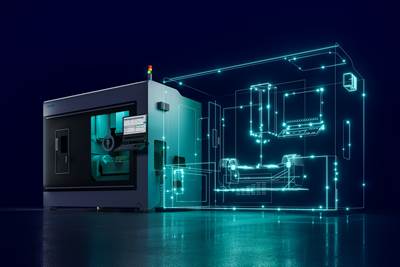

Read MoreSiemens' CNC Control Facilitates Digital Transformation

Eastec 2023: The new control generation is designed to provide machine builders and end-users with a full digital twin of the machine tool and machining sequences.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

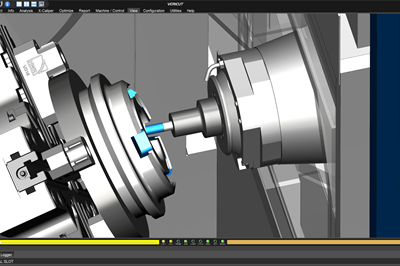

Read MoreCGTech Simulation Software Optimizes Machining Operations

Eastec 2023: Vericut detects errors and potential collisions in NC programs prior to running them on machines for the first time, so programmers can send programs to a machine with the confidence that they’ll run without incident.

Read MoreSiemens Upgrades CNC Operating Software Solutions

Sinumerik CNC software release 4.8 is designed to improve the speed, precision and safety of intermediate milling, turning and grinding machine tools, with simplified ISO code programming.

Read More

.jpg;maxWidth=300;quality=90)