CAD/CAM

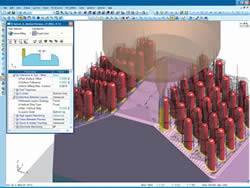

Practical Tips For High Speed Machining Of Dies And Molds

In die/mold work, the programmer can make the HSM process dramatically more effective. Here are some tips.

Read MoreMaking Programming Hands-Free (Almost)

Feature-recognition CAM software helps this technology company's internal mold shop deliver critical molds more quickly. A programmer is still needed, but the software automation saves considerable time.

Read MoreAn Affordable, Secure Way To Exchange 3D CAD Models

Shops no longer need 3D CAD software to view 3D CAD models.

Read MoreSteering Clear Of Corner Concerns

Tool paths based on constant stepovers often get an end mill into trouble when it heads into a corner. Using the tool's angle of engagement as the constant avoids this difficulty.

Read MoreCAD/CAM Considerations For Micromilling

Milling with tools that are smaller than 100 microns in diameter presents equipment design and toolpath-generation challenges. This NC software maker offers strategies for creating safe, optimized tool paths for micromilling.

Read MoreMaking A Flexible Machine Tool More Flexible

Multitasking cutting tools can maximize the flexibility of multitasking machines.

Read MoreThe Changing Face Of CNC Programming

The Future of Machining - 2005 Efforts to create a CNC-usable product data model are inching forward, but in the meantime, advances in CAM software will make the programmer's job function super-efficient rather than superfluous.

Read More

.jpg;maxWidth=300;quality=90)