CAD/CAM

Buying Preferences Of Moldmakers

CIMdata recently conducted an extensive worldwide study of moldmakers to better understand current moldmaking operational processes and technologies being employed, issues being faced by mold producers, their plans to remain competitive in a tough worldwide environment and the requirements that they place on their CAD/CAM suppliers. One of the many areas examined and presented in this 135-page report was that of CAD/CAM buying preferences.

Read MoreControl Helps Museum Fill In The Gaps

Today, with Hollywood leading the way in the precise, high tech creation of real and imaginary forms, anything seems possible, such as bionic people, dinosaurs or extra-terrestrial beings. But the final machining of the prototypes, molds and net shapes of these forms is still being done the 'old-fashioned' way with lathes, mills, grinders and routers.

Read MoreShoe Manufacturer Improves Time To Market With CAM Software

Speed is one of the selling points athletic shoe manufacturers use to market their products: Buy their shoes and you'll run faster. But speed is not just a factor in selling shoes; it has become an essential in their manufacture as well.

Read MoreCompany Increases Manufacturing Capability With CAM System

This manufacturer is a 'one stop shop' offering custom machining and manufacturing, precision sheet metal work and prototyping, as well as long and short production runs.

Read MoreShop Owes Growth To CAD/CAM Versatility

This shop's programmer/operators, equipped with the most versatile CAD/CAM software they could choose, moved on to the tool path and cut more combinations of amazingly diverse parts, as a company confident of its ability to meet any of its customers' molding, machining or manufacturing needs.

Read MorePushbutton Die Making

High speed milling let this automotive forging company reverse a decades-old practice and bring die making back in house.

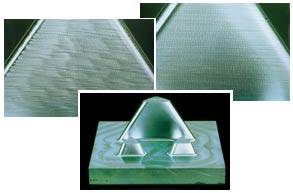

Read MoreCurve Interpolation For Less

When the CNC executes the program faster, a higher feed rate becomes possible. Precisely this benefit has compelled many mold makers in particular to inquire about NURBS.

Read MoreA Better Process For Bases And Plates

In a mold shop, the model of the customer's part gets used in two parallel processes. One of these is core and cavity machining, in which CAM software generates complex tool paths to let CNC machining cut the shape of the part in metal.

Read MoreCAM Software Makes Responsiveness A Cash Crop

This company provides design and engineering services to oil drillers, cell phone service providers, companies that make clean water systems and any other business looking for effective problem-solving done at breakneck speed.

Read More