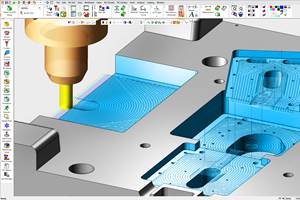

Practical Tips For High Speed Machining Of Dies And Molds

In die/mold work, the programmer can make the HSM process dramatically more effective. Here are some tips.

Share

Increasing spindle speed, reducing chip load and rounding the sharp corners in the tool paths are some of the important considerations for successful high speed machining. However, NC programmers and machinists who stop at these considerations find themselves either breaking tools or scaling back on parameters such as stepover, feed rate and depth of cut. This is serious, because if high speed machining does not reliably deliver significantly faster throughput, then the high speed machines are not worth the investment.

More successful machinists and programmers realize that high speed machining is a fundamentally different way to machine. They look for ways to continuously improve their processes on high speed equipment. Some of the improvements can be quite simple. That is the case with the tips presented here. What follows are ideas that you might adopt today to better realize the value of your own high speed machining process.

1. Aim For Constant Material Removal

In an optimized system, all elements operate just below their peak capacities and none of them are overloaded. This is what we should strive to achieve in high speed machining. To avoid tool damage, speed and feed should remain in bounds for the peak loading encountered in the tool path. However, setting speed and feed in this way leaves the tool cutting slower than it should during all of the non-peak-loading periods. We want the tool instead to operate at the edge of its threshold throughout the cut. That is, we want constant material removal or consistent chip load. If there is inconsistent chip load, then one of two things is happening: Either the process is damaging tools, or else it is running too slowly.

Optimizing the rate of metal removal in roughing is the most important step in CAM programming. The depth of cut and stepover recommended by machining tables for a given combination of tool and material assume that you are roughing at the same stepover throughout the tool path. If your path involves a slotting move or careless corner embedding, however, then the tool could encounter a lot more material than anticipated.

Simple offset patterns work well only if all sides of the material to be removed are open. If you have walls adjacent to the area you are trying to rough, then this pattern could cause the tool to slot through material. (See Figure 1.) A better option is to use a follow-part offset pattern. Such a pattern avoids slotting by starting away from the part walls and working in. Even though this tool path includes many rapid moves, the overall machining time is reduced because of the increased stepover this pattern allows. An even better option is to use a trochoidal pattern that monitors the amount of tool embedding to maintain a consistent threshold.

2. Stick To Z Levels

In most cases, finishing 3D surfaces through Z-level operations (also known as “water line” or “constant Z” machining) provide much better material engagement and more consistent finish than projected finishing operations. Z-level operations guarantee that the material removal rate and tool engagement are consistent, with fixed axial depths of cut and top-down cutting. In contrast, projected raster operations climb up and down depending on the part geometry, suffering significant spikes in axial engagement when they climb steep slopes. Again, if these areas of peak loading do not damage the tool, then the non-steep parts of the process are cutting too slowly.

3. Know Your Controller

Some controllers feature high speed processing modes that provide for aggressive acceleration and deceleration rates during roughing operations where submicron accuracy is overkill. For example, on Makino machines using Fanuc controllers, simply turning on the M251 code before roughing cycles could reduce roughing time by 30 percent. Siemens’ Sinumerik 840D controller offers a similar high speed cycle (Cycle 832), which allows users to set various velocity optimization modes. Advanced CAM systems such as NX from UGS provide customizable operation templates where these settings can be set up once and then used automatically.

4. Shorter Tool Length is Better

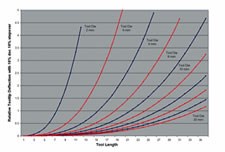

A cutting tool is a cantilever beam, with the cutting force acting at its free end. Proven physical equations show that the deflection is exponentially proportional to the length of the cutting tool. For example, a 6-mm diameter tool set at 24-mm length could deflect 50 percent more than the same tool set at 20-mm length. (See Figure 2.)

The deflection at the cutting edge is the primary cause behind various negative effects such as chatter, wobble and impact loading. Hence it is important to keep this deflection to a minimum. Reducing the tool length is the easiest way to control tool deflection and still maintain high material removal rates. The tool length advisor in NX Machining from UGS prompts the user with the shortest length of the tool that would be sufficient to machine a given geometry.

5. Never Climb Straight Up

Any hiker can tell you that climbing a hill on an angle reduces the effective slope and makes the going easier. Steep hills are hard on end mills as well, because they engage more material on the uphill side. As the slope gets steep (on the draft faces of most die cavities and cores, for example), the axial engagement can spike dramatically. This could break the tool.

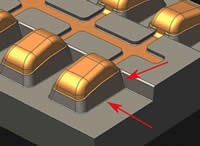

There are two techniques to mitigate the engagement spikes that result from steep climbs. One is to change the zigzag angle so that the tool approaches these steep walls at a 45-degree angle rather than plowing head-on into them. Climbing up at an angle reduces the effective slope and relieves the overloading. (See Figure 3.) A side benefit of cutting at 45 degrees is that the fillets running at 0 and 90 degrees are only momentarily engaged during each pass, giving the tool time to recover. Cutting parallel to these fillets would otherwise increase the load during a few passes, possibly elevating cutting tip temperature and weakening the tool.

Another technique to avoid overloading the tool while cutting steep walls is to pre-machine these walls using Z-level operations. Zigzag area milling the entire part can come next, but the pre-machining of these walls means that the zigzag milling can avoid loading the tool when these walls are encountered.

6. Interact With Your Tooling Designer

Certain features require more careful programming and machining than others. Potential examples include the small concave fillet radii and narrow slots that are often encountered in mold components. Educating your tooling designer about the machining challenges of these features could make your life a lot easier. For example, most shut-off mold surfaces do not need tight vertical fillets and slots. These could easily be modified to make machining of these parts easier and quicker. (See Figure 4.) In short, effective high speed machining may involve not just spindle speed, feed rate and toolpath smoothing, but also attention to the nature of the tool paths themselves, and it may even involve greater communication as well.

About the author: Edwin Gasparraj is a product manager with UGS based at the company’s Milford, Ohio, office.

Related Content

For This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreRead Next

Constant Material Removal: The Key To Hard Milling

Features of the CAM software can keep the cut from exceeding the tool’s limits, without compromising part quality or productivity.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More