Basics

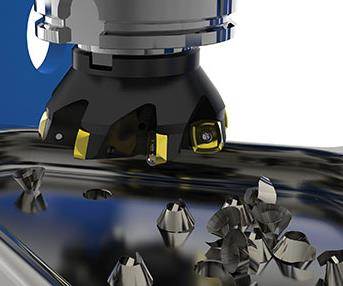

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read More5 Tips for You To Get the Most From IMTS

Plan, explore, think of the future: Here is how to get the most from the major manufacturing event that many will be experiencing for the first time.

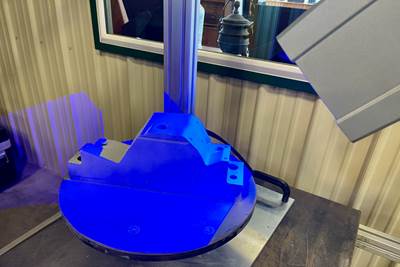

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

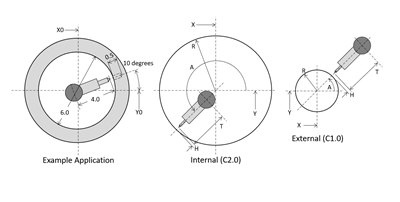

Read MoreHow to Drill Holes With a Right-Angle Head

Drilling with a right-angle head in a machining center spindle can be tricky – doubly so if the hole must be peck-drilled. A custom macro and careful attention to positioning help ensure smooth production.

WatchHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read More5 Reasons Why Machine Shop Ownership Is Changing

Mergers, acquisitions and other ownership changes are an effect of Boomer-age shop owners retiring, but only in part. Also important: The way we think about machining has changed.

Read MoreWhen Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

Read MoreUnderstanding The Four Major Behavioral Styles

Companies today are expanding the role of teams in the workplace in an effort to empower employees and improve organizational effectiveness. The more we try to work as a team, the more important it becomes to recognize that people exhibit different behavioral styles.

Read More5 G-Code Tips for Increasing CNC Efficiency

Optimizing G code is a low-cost way to improve CNC efficiency without sacrificing usability and safety.

Read MoreChoosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

Read More