Basics

Understanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

Read MoreUnderstanding Errors In Hand-Held Measuring Instruments

Different instruments (and different operators) are prone to different errors.

Read MoreWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreHow To Calibrate Your Calipers

If you’re interested in calibrating your own digital, dial or Vernier calipers, here are some steps to take to make sure it goes off without a hitch.

Read MoreHow to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read More6 Steps to Take Before Creating a CNC Program

Any time saved by skipping preparation for programming can be easily lost when the program makes it to the machine. Follow these steps to ensure success.

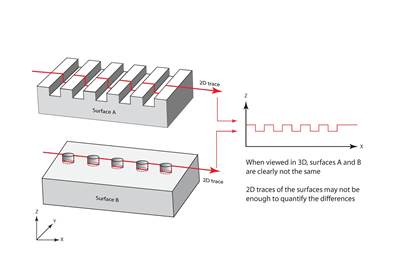

Read MoreWhen Manufacturers Should Use 3D Measurement for Surface Finishing

Two-dimensional (2D) surface profiling systems are the standard for quality assurance in manufacturing, but some applications demand 3D measurement systems.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreKey CNC Concept No. 1—The Fundamentals Of Computer Numerical Control

Though the thrust of this presentation is to teach you CNC usage, it helps to understand why these sophisticated machines are so important. Here are but a few of the more important benefits offered by CNC equipment.

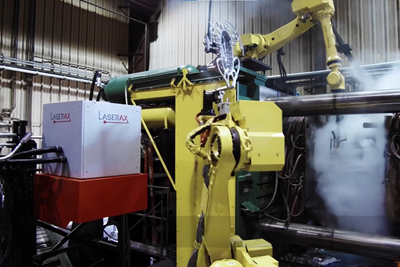

Read More5 Tips for Automating Laser Marking With Robots

Automating laser marking can be a useful way to increase robots’ utilization, but the process requires careful planning for success.

Read More