Share

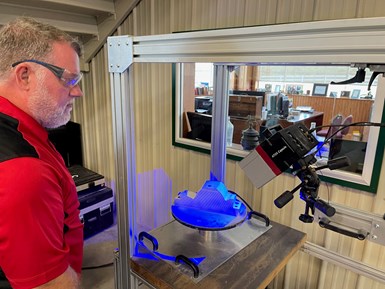

A structure light scan of an automotive die insert machined at Integrity Tool. Among other measurements, the scans can calibrate features that have been machined into the part to interface with modular Schunk workholding tools.

The challenges for Integrity Tool started with saw-cut blanks from its supplier that were never truly square. Many of these workpieces were destined to become die inserts for a major automotive company — highly complex, high-value, one-off parts for a customer that represented a significant revenue source for the shop. The first blow was that Integrity Tool was essentially paying for squaring these faulty blanks twice: An initial payment to a supplier that charged extra for “squared" blanks, then an additional cost for having the six-sided blanks properly squared, either in-house or at a second shop.

The next challenge followed right on the heels of the first.

The go-to workholding method for the squared workpieces was what some people at the company referred to as “Swiss-cheese plates.” These were plates of hot-rolled A36 low-alloy steel about an inch-and-a-half thick that Integrity Tool used as temporary, disposable workholding devices. Its method was to drill, tap and ream dowel holes in the plate to match the workpiece features, bolt the part into the plate, and then machine op 2.

Moving the plate to another machine tool for secondary ops tended to create problems. Once the part was removed, machinists had to sweep the plate with an indicator to locate the correct holes — or simply drill new ones — and then level the plate and begin the next op.

This not only added significant setup time to the process, but also wore down tooling and introduced tolerance stack-up into the production cycle. Drilling new holes into the sacrificial plate also added programming time, and decking the plate risked removing too much material and making the plate too thin, a condition that allowed it to bow and flex during machining.

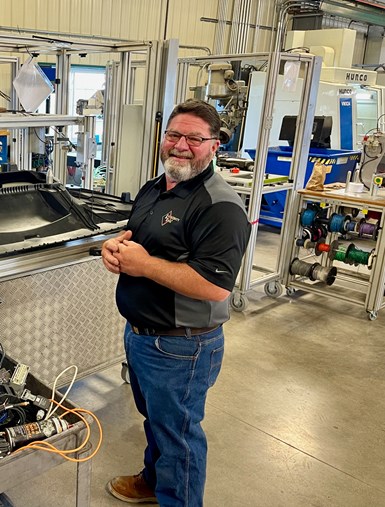

“It was a nightmare,” says Jeff Lewis, founder and president of Integrity Tool, a precision machining and custom automation solutions provider in Cox’s Creek, Kentucky. “You fill that plate up, make Swiss cheese out of it and then you throw it away.”

Unnecessary costs. Setup issues. Longer lead times. Increased difficulties holding tolerances through multiple operations. A cascade of issues that began the moment new material hit the shop floor.

The solution to all these problems was not cheap, but Lewis says that it has already paid dividends many times over.

Integrity Tool sits on a 380-acre cattle farm — both of which are operated by Jeff Lewis, along with the help of his family and employees.

CNC on the Cattle Farm

To find Integrity Tool you will need to drive 45-minutes southeast from Louisville, deep into a rolling expanse of fields and farmhouses. I’d been instructed to search for the name of the company in my GPS rather than the address itself, in order to avoid some digital quirk that had led other visitors astray. “You’ll see cows out front,” I was told. “Just keep going up the hill past them and you’ll find us.”

Integrity Tool is the only machine shop I’ve visited that sits squarely in the middle of a cattle farm — a farm that Jeff Lewis has operated for most of his life and the place where he raised his family. The 55-year-old Lewis still wakes up at 5 a.m. to work on the farm’s 380 acres. Around 7 a.m. he turns his attention to the shop, where he typically works until 6 or 6:30 p.m., eats dinner, and then heads back out to work on the farm for another two or three hours.

Jeff Lewis started Integrity Tool in 2000 with a manual mill and welding equipment that he used to machine and repair farm equipment. The company has now grown to include both high-precision CNC machining and custom automation solutions.

Lewis opened Integrity Tool in the year 2000 as a place to weld and machine broken farm equipment, both for himself and for his neighbors. His first machine tool was a manual mill. When business began to pick up, he purchased a CNC lathe that he learned to use on his own. Fast-forward to today, and the company maintains a staff of 20, including CNC programmers, machinists, and design and electrical engineers that run the automation solutions side of the business. The company’s fleet of CNC machine tools now includes a DMG MORI NLX 2500 mill turn, a DMU 65 five-axis, an NVX 5100 VMC, as well as three Hurco vertical CNC mills.

One of those employees brought on by Lewis is Tony Elder, Integrity Tool’s vice president of operations as well as a first cousin who grew up with Lewis. Lewis convinced Elder to leave his job as a design engineer for an automotive OEM and join Integrity Tool. In turn, Elder has convinced Lewis to invest significantly in equipment and technology, including an Atos structured light scanner along with a DMG MORI NHX 5000 HMC, primarily to expand the tool-and-die part of the business.

Integrity Tool has also invested significantly in modular workholding tools from Schunk that have solved almost all the problems associated with the saw-cut blanks and sacrificial plates.

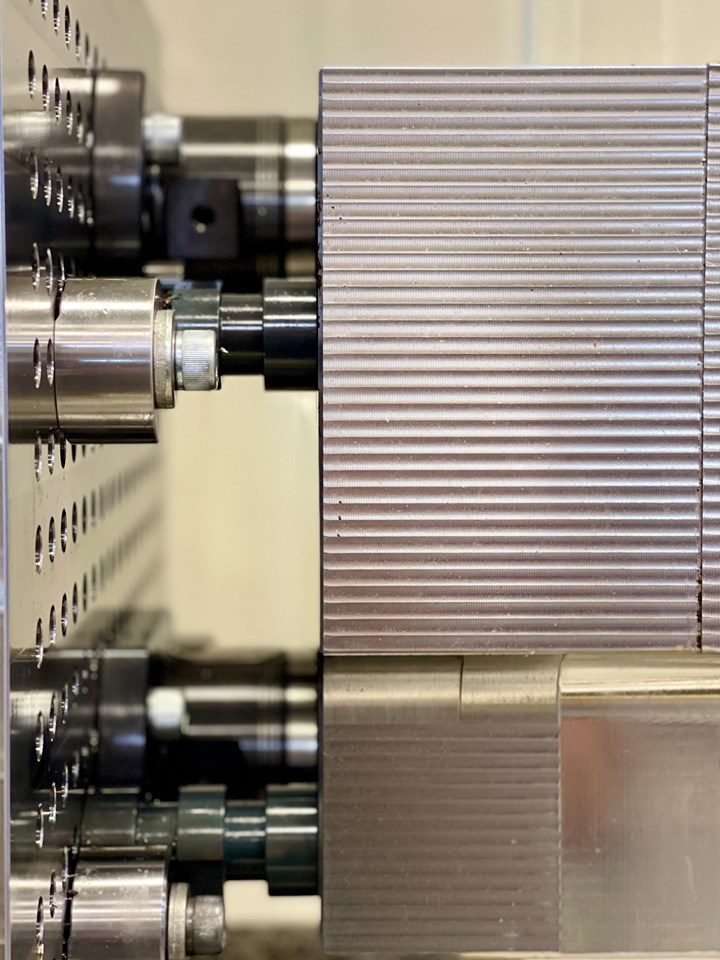

A Schunk KSC-F 160 vise with swivel plate jaws clamps 3 mm of material and allows five sides of this die block to be machined in one setup.

Rather than outsourcing the saw-cut blanks to be squared, the shopnow utilizes KSC-F 160 single-acting vises with swivel plate jaws to grip the blanks and square them in-house. The swivel jaws clamp on just 3 mm of material and allow five sides of the die block to be machined in one setup. The ability to square saw-cut blanks alone has saved considerable cost and decreased lead times, but it also allows Integrity to machine features into the die steel during the same operation — features that will receive the workholding supplier's Vero-S pins for later ops.

Schunk WDM modules affixed to a grid plate inside a DMG MORI five-axis machine. By affixing parts to the grid plates with the Vero-S system, Integrity’s machinists can maintain accuracy by establishing an A-datum, a B datum in X or Y, and a floating C-datum.

The Vero-S pins mate parts to tombstone-mounted grid plates via Schunk WDM clamping modules, seen here. Now all the machinists need to do is flip the part from the vise onto the machined grid plate to mate with the Vero-S pins for the next operation — a quick changeover that allows the parts to move across multiple machines using the same setup.

By affixing parts to the grid plates with the Vero-S system, the machinists can now maintain accuracy by establishing an A-datum, a B datum in X or Y, and a floating C-datum, depending on the size and shape of the part. Z-height variations and adjustments can be made by using differently sized WDM modules. The accuracy and consistency of these setups across multiple ops allow Integrity Tool’s finished parts to hold tolerances in the range of +/-0.0004 to 0.0008 inch, all while decreasing setup times and increasing throughput. This frees up time for Integrity’s machinists to focus on other aspects of their jobs, such as improving metal removal rates and implementing programming efficiencies.

Let There Be Light

On its own, the investment in high-end workholding was not enough to ensure the accuracy needed to machine complex, one-off die inserts for a major automotive company. To verify tolerances, Integrity Tool overlays scans of each die insert on top of the original using structured light scanning technologies — non-contact optical devices that project laser light patterns on dies and molds and then use a high-precision camera to read and transmit this data to software to generate a precise 3D map of the part.

Tony Elder brought his experience as a design engineer for a major automotive company to Integrity Tool, where he has spearheaded new technology integrations such as this Atos optical 3D scanner.

Problems arose when the OEM fined-tuned the dies after performing the original scan. Even small adjustments like welding touchups can cause the original scan data from the die manufacturer to become obsolete. Because of this, and because Tony Elder was familiar with this process from his previous job, he convinced his old friend Jeff Lewis to make a six-figure investment in an Atos high-speed 3D scanning system. Lewis and Elder now make it part of their routine to visit customer facilities across North America to obtain the latest die scan data before they begin machining die inserts.

“When they pull our parts off the shelf, they expect them to work,” Elder says. “This scanning data is really just a big insurance policy for them. Because if they crash the tools on a fully hardened die, it might be a catastrophic failure that just blows up. And when it blows up, they don't have a spare die sitting around because it's a million-dollar tool. But they call us for a spare insert, so they have a backup.”

Now Integrity Tool can overlay a scan of a new die insert over the original die insert scan performed at the OEM and generate a color-coded map of key feature tolerances. They can also scan parts in-process to ensure workholding is aligned before machining operations continue.

“I want to brag on Tony for a minute,” Lewis says at the end of our visit. “I’m the owner of the shop, but it’s because of the people I hire it’s been successful. Tony and I grew up together, played football together and all of that, but it takes everyone’s contribution to succeed with automation and high-precision machining. Our success is all because of guys like him along with the rest of our employees.”

integritytool-ky.com |502-252-5800 | jlewis@integritytool-ky.com

Your intrepid reporter, watching his step in a cow pasture outside of Integrity Tool in Cox’s Creek, Kentucky.

Related Content

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreFive Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

Die Makers Adapt to Challenges All Machine Shops Face

Die shops offer examples of adapting to the skills shortage and excelling at difficult machining. Plus, why reshoring should begin with die tooling.

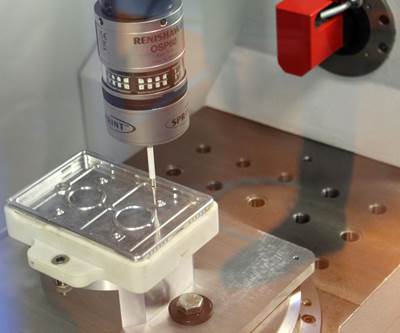

Read MoreOn-Machine Scanning Probes for Speedier Setups

Renishaw introduces new on-machine, touch-probe scanning technology to enable faster workpiece setup and inspection cycles.

Read MoreGripper Finger Change System From Schunk Reduces Setup Time

Schunk claims its toolless jaw quick-change system reduces setup times to a minimum, therefore increasing the productivity and flexibility of the entire system.

Read More