Share

Single-sourcing with key suppliers such as a single vendor for machine tools leads to various efficiencies. Single-sourcing with one cutting tool supplier, Badger Mill, laid the groundwork for an efficient and comprehensive week of testing to develop the shop’s expertise in materials that would represent more of its business in the future. Photos courtesy of JR Machine.

How does a machine shop make good use of the downtime resulting from a lull in demand?

To be in the business of CNC machining is to meet this opportunity from time to time. The sectors machine shops serve are cyclical. A lull in business may not be the kind of opportunity any shop wants, but “opportunity” is precisely what this pause potentially offers, and likely a valuable opportunity. The shop that focuses, invests and acts during this time has the chance to prepare itself — to get to a different level of performance and capability — before active business conditions return.

Tim Tumanic is the shop’s president and CEO. In 2019, he recognized the business was too reliant on oil and gas work. He made the choice to diversify into aerospace.

JR Machine offers an example. The 36-employee shop in Shawano, Wisconsin is busy now, but it wasn’t nearly as busy in 2020. Before the pandemic, company president and CEO Tim Tumanic had made the decision to diversify away from the shop’s reliance on the oil and gas sector, but that decision didn’t come fast enough to save the shop from the downturn resulting from the pandemic fully arriving in the U.S.

“Our business was off 35%,” he says.

That 35% was the window of opportunity: open capacity that could be put to use. In line with its aim to diversify, the shop continued to pursue AS9100 certification for aerospace manufacturing work. It obtained the certification in 2020. Even so, the shop’s team was not yet skilled with aerospace metals. “We did not have a high level of experience in high-temperature alloys,” Tumanic says.

So, what was the way to get this experience? How long does it take for a machine shop to elevate to the next level in terms of its efficiency and proficiency with a challenging class of materials?

Answer: If you really focus, it takes one week.

A special week.

Busy times would return. Aerospace opportunities would come. “We did not want to be in a position where we had to put a job on the machine today and figure out how to run that material in time to deliver the part tomorrow,” Tumanic says.

To prevent this, JR Machine devoted its downtime to learning. Tumanic and the team created an event — a special week in which cutting tool suppliers were welcome to visit the shop while JR Machine evaluated their tools' performance in high-temperature alloys and explored different cutting strategies and parameters in these materials.

This learning entailed an investment. There was the machine time, which was available. There was also the metal. JR Machine spent about $15,000 on Hastelloy, Inconel 625 and 718, Monel and titanium 6Al4V for the sake of this testing (as well as 15-5 stainless, which was also included though not a high-temperature alloy).

One other investment was in design engineering. For this event, JR Machine invented a test part representative of aerospace machining.

Testing tools brought a lot of attention to a machine that otherwise might have been idle for lack of work. In this photo taken during the test week, seen here from left to right are Kevin Manser with cutting tool provider Iscar, Shane Kunschke and Brock Jaskolski of JR Machine, Todd Fritz of Iscar Metals and Kyle Rosenberg of JR Machine.

Single-Source Supplier Support

One important element of the shop’s operating philosophy made this idea for a week of testing aerospace-alloy cutting tools much easier to pull off. JR Machine commits to single-source relationships with its suppliers. For example, the company is a DMG MORI shop. Relying on machine tools from one vendor simplifies service and ensures close attention from that vendor, while also making it easy to cross-train and redeploy employees. And for tooling, JR Machine trusts one distributor: Badger Mill Supply of Oshkosh, Wisconsin.

Badger Mill was not expert in aerospace machining, either. Its region, northern Wisconsin, is not home to a significant amount of work in this sector. But this distributor represents vendors who do have expertise and products for this sector. As a supporter of the event the shop organized, the cutting tool distributor brought in cutting tool makers one by one.

“We didn’t want competing cutting tool companies here at the same time. That would be unfair,” Tumanic says. But different cutting tool vendors represented by Badger had the chance to see the test part model in advance and bring their best tool offerings for producing that part.

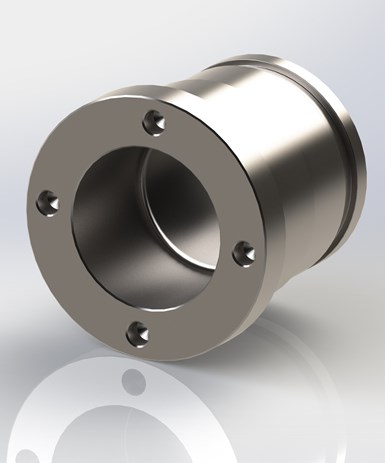

The test workpiece for cutting tool evaluation requires turning, grooving, drilling and boring.

The test part was a hypothetical aircraft component with features similar to aircraft parts that JR Machine had been quoting. The cylindrical part measures 4.900 inches in diameter at its widest portion and requires machining includes flanges and holes. The part offered the opportunity for drilling, boring, turning and ID/OD face grooving in all the various materials the shop wanted to consider. One of the shop’s CNC turn-mill machines was devoted to running this part through the week.

A week on one machine might not seem like a lot of time, but that week is more than it seems when the capacity is devoted entirely to learning. After that week, JR Machine’s team now knows, in a way it could not have known before, exactly which tools to specify for particular features in particular alloys, and the speeds and feed rates at which to run those tools. The knowledge is now part of the shop’s procedures. “It has gone into our process routings,” Tumanic says.

Real aerospace work is similar to the hypothetical test part.

Meanwhile, every bit as valuable was the experience of what the shop failed to learn during this testing — that is, finding out in a safe context what it still doesn’t know.

Drilling Monel the Next Step

“We could not drill Monel,” Tumanic says, describing the key discovery in this area. “We found no good solution for holes in this material.”

Obviously, this is a crucial insight. It represents valuable self-awareness for the shop, saving it from the danger of perhaps too-confidently quoting on a Monel opportunity that comes along.

The insight also provides an example of why this sort of event — this structured means of advancing the shop’s process knowledge — is too valuable not to try again. It turns out, a week of machine time plus $15,000 of material is a bargain for what the shop is able to learn. The next event will focus more specifically on hole-making, with particular attention to Monel.

However, the next learning event will be much harder to schedule. The lull is past now; the shop is busy again. There is no good opportunity now — no idle machine capacity waiting to be applied to test cutting. One reason is because the oil and gas work has bounced back. But to compound the busyness, aerospace opportunities are now being realized. The shop is running parts in both Inconel 625 and 718 that, as it happens, resemble the hypothetical test piece. During its downtime, with the learning opportunity it devised, the shop was preparing for the future even better than it imagined.

Drilling remains a challenge, specifically in hard metals such as Monel. The awareness of this is valuable, and advancing drilling will be the focus of the next event.

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreHow to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)