5 Tips for You To Get the Most From IMTS

Plan, explore, think of the future: Here is how to get the most from the major manufacturing event that many will be experiencing for the first time.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

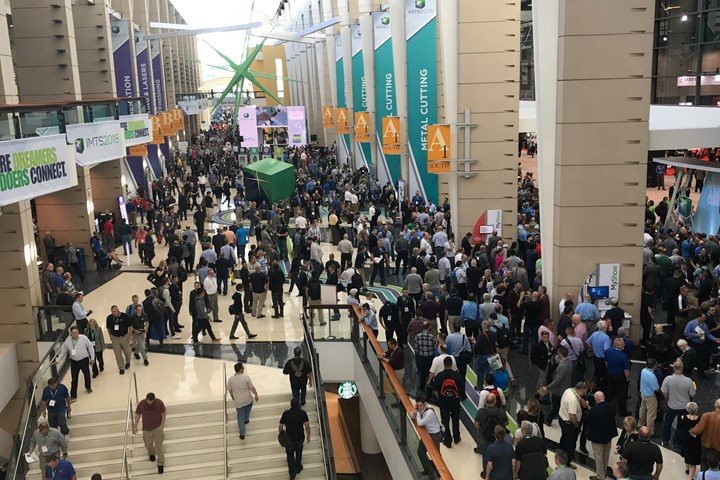

For first-time attendees, but also as a refresher to those of us who may be rusty after so long without attending the show, here are a few tips to consider — advice for getting the full value from the experience of attending IMTS:

1. Make a Plan

The show is huge. The size of the venue, the scope of each hall and the sizes of the booths of major exhibitors all have to be seen to be understood. Just wandering through IMTS, and only that, is unlikely to deliver you to all the discoveries and encounters that will most benefit your shop. Sensory overload combined with the distances involved make wandering a risky strategy.

Make a plan instead. Pause for a moment to do this. List the exhibitors you know you want to visit. Note their booth numbers, and cluster your visits by exhibit hall (North, South, West, Lakeside Center) to minimize walking time. You can use the MyShow Planner tool on IMTS.com to help.

Consider this: If you could manage to give serious attention to three exhibitors per hour over the course of seven hours per day for two days of planned visits at the show, then those would be two intense, busy and probably exhausting days — and they would not even get you to 2% of the show. Taking time to identify which exhibitors to visit is an important investment.

2. Be Comfortable

In the pages of Modern Machine Shop, the advice we routinely give to readers attending IMTS is: Wear comfortable shoes.

The larger point is this: Be comfortable. Carry the resources you need to remain focused. This might mean snacks, water or medication. It probably means backup power for your phone and a pen and notepad. You are here to discover and absorb a lot of possibilities. You don’t want some nagging lack to limit your bandwidth or stand in the way of what you might see.

3. Explore

Wandering is not effective as a sole strategy, but it works well as an aid or augment to your known plans. In addition to what you know you want to see, make time for what you will want to see that you do not know about yet. The best way to do this: Once you have determined how much time you need to visit the companies you know you want to see, add another half-day. That is, an open half-day just to walk slowly, look around and see what catches your eye.

You are not necessarily looking for new technology or new products during this time. The discovery you are apt to make likely instead involves some possibility that is simply new to you, such as a long-established tool, machine or system that perfectly matches a challenge or opportunity only now presenting itself to your shop.

4. Think About the Future

IMTS comes only every other year. Many shops do not attend every one. What capabilities is your shop likely to need in the coming two to four years?

Think big. Two to four years is enough time for significant change. If business expands significantly, what type of capacity is your shop likely to need? What types of automation are warranted, given the likelihood that adding personnel will be challenging? At this IMTS, robots are liable to get more attention than at any other previous year for the show.

And then there is additive manufacturing. Producers and OEMs across all sectors recognize that 3D printing is likely to account for an important share of their part production in the future. IMTS has changed significantly in recognition of this. It has opened to encompass AM, with the AM Pavilion now representing a sizable exhibit area at the show.

5. Be Inspired

Machining is a community. It’s just that it is a big community performing a broad variety of work across many sectors. That community cannot come together often, and it missed an opportunity to do so two years ago, but representatives of the entire scope of that community are here with you at IMTS now.

Look around! See how big industrial metalworking is and how much it does. We will all go back to our own shops and our day-to-day concerns, but thanks in part to IMTS, we will bring new tools and technologies to bear that will let us meet the problems and the opportunities more effectively. And thanks to IMTS, we will also carry with us — for the two years until this vast community can come together again — a sense of the scope and significance of the work we are all advancing, and the number of people who join us in it every day.

Related Content

Chiron Group Unveils Virtual Showroom & Live Demos at IMTS 2024

Chiron Group combines the best of both worlds at IMTS 2024, featuring live demonstrations of their Micro5 and Mill 2000 machines, alongside a cutting-edge virtual showroom. This innovative approach allows visitors to explore Chiron’s full product lineup without the logistical challenges of transporting large equipment.

Read MoreSMW Autoblok Workholding, Automation Solutions Optimize Milling, Grinding Operations

IMTS 2024: SMW Autoblok presents the WPS XL for milling, measuring and grinding operations with five-axis and large part workpieces, as well as several products from its electronics and automation line.

Read MoreTrak Machine Tools Lathes Offer Compact, Heavy Duty Performance

IMTS 2024: The Trak TC2 and the Trak TC820si are compact lathes designed for production applications.

Read MoreL.S. Starrett Inspection Technology Optimizes Data Collection, Measurement

IMTS 2024: The L.S. Starrett Co. is demonstrating a range of quality control inspection technology, specifically for data collection, vision systems, measurement systems and more.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)