Drilling with Modulation Delivers Pecks for Free

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

Share

This animation illustrates MAM.

Almost anyone who has ever drilled a hole knows the value of a peck drilling cycle. Periodically backing up the drill helps manage both chips and heat within a deep hole. In recent years, Purdue University researchers have worked to develop a technology based on a straightforward idea: If pecking every few seconds during the drilling cycle is good, then pecking hundreds of times per second might be dramatically better still.

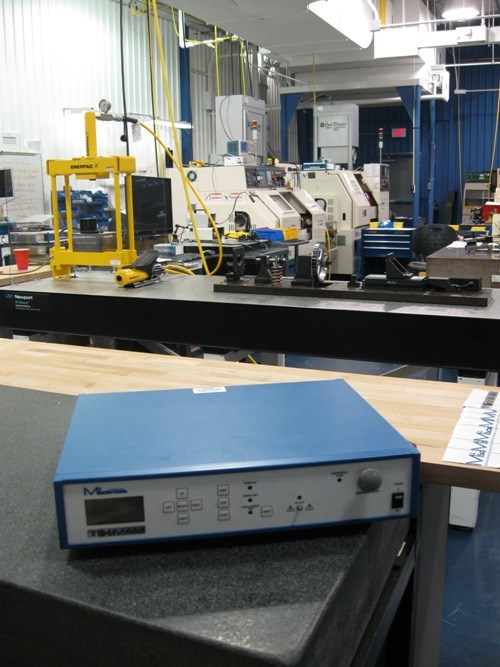

Modulation Assisted Machining (MAM) is the commercial name for this now-patented technology—sold by a company incubated by the university, M4 Sciences of West Lafayette, Indiana. Thanks in part to funding from the National Science Foundation and Indiana’s 21st Century Fund, M4 Sciences was able to take an idea that had been proven in laboratory settings and translate it into a self-contained product that can be installed and applied on production CNC lathes.

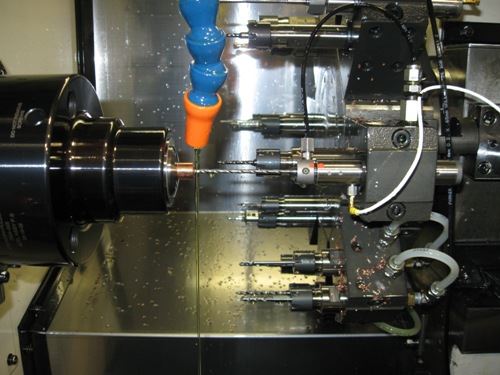

So far, lathes are the only target for this technology, which applies strictly to center drilling applications. The company’s “TriboMAM” modulating unit loads in the turning machine’s workzone like a toolholder and connects to a small, independent controller. Accommodating drills up to 5 mm in diameter, the system is best suited for compact CNC machines, particularly Swiss-type lathes. For these machines, the technology offers the potential for dramatically more productive drilling—particularly in titanium and other hard metals.

With MAM, the peck drilling cycle is free. The TriboMAM unit oscillates the drill as it cuts, making the peck continuous. This does away with the delay of programmed peck cycles, while also permitting more aggressive feeds, says Jeff Bougher, president of M4 Sciences. Typically, the company promises drilling cycle time reductions of at least 50 percent.

The minutely controlled pecks occur at frequencies ranging to 1,000 times per second. Actual frequency and amplitude are both determined by the system’s controller, based on drilling parameters input by the operator (speed, feed rate, number of drill flutes and drill diameter). Beyond cycle time improvement, Mr. Bougher says the benefits of the oscillation include the following:

• Better lubrication. Continuous oscillation leaves room for the lubricant to get into the cut, he says. Keeping lubricant at the cutting edge makes through-tool coolant even more effective.

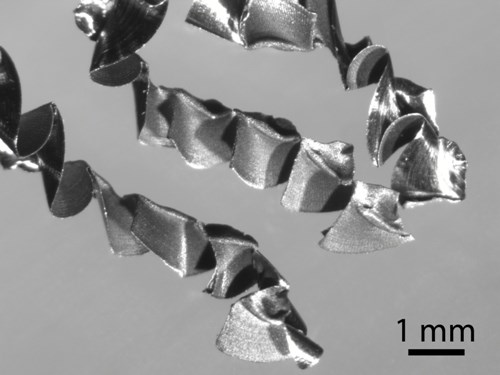

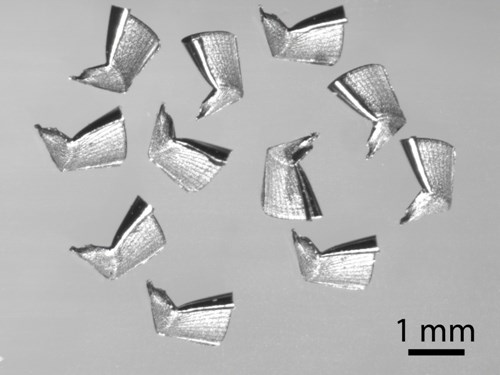

• Better chip evacuation. Chips are small thanks to the rapid pecks. This ultimately produces more consistently accurate holes because chips no longer get bound up with the tool to distort the hole’s shape.

• Consistently shaped chips, which lead to a more consistent drilling process overall.

This final benefit might well be the most valuable, Mr. Bougher says. Manufacturers of high-value parts, such as aircraft fuel system components and orthopedic screws, increasingly do not find their efficiency gains solely by running faster. The savings also come from engineering a process that runs with less human oversight. Doing this requires machining operations that perform predictably—cut after cut and hour after hour.

MAM’s ability to control the chip contributes to this predictability, he says. What’s more, users get this consistency and predictability essentially for free, because there is no need to reduce cycle time to make the cutting more consistent.

Related Content

Arch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreSandvik Coromant Inserts Provide Stable Turning of Aerospace Components

The new insert grades GC1205 and GC1210 cover a large application area within last-stage machining and intermediate-stage machining when turning aerospace engine components.

Read MoreForkardt Hardinge Swiss Workholding Provides Reliable, Consistent Performance

The company’s Swiss collets are designed to securely hold parts without marring surfaces, minimizing vibration to ensure smoother machining, enhanced accuracy and extended tool life.

Read MoreRead Next

Video: Modulation Assisted Machining

This footage shows the effect of a techology that speeds and simplifies center drilling by oscillating the drill through many pecks per second.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)