Making Research Real

Rolls-Royce expands upon a successful formula for developing manufacturing innovations beyond university research and into production.

Share

According to aircraft engine maker Rolls-Royce, the part in the lead photo is significant for reasons that go beyond just the manufacturing technology used to produce it today. This part also signifies the value that Rolls-Royce has found in realizing a new approach for developing the manufacturing technologies of tomorrow.

The part is a fan rotor from the company’s Trent 900 jet engine. Such an engine includes various bladed disks. The blades have precise contours that demand complex machining. The disks have deep and intricate machined slots for holding the blades. And in the turbine section of the engine in particular, the high forces and extreme temperatures require the blades and disks to be made from some of the most difficult-to-machine nickel-based alloys ever created. Thanks to all of these factors and many others, jet engine blades and disks are among the most challenging production parts in any industry.

Yet they are just the start. A jet engine includes many other challenging components as well—components with demands relating not just to machining, but instead to forming, forging, joining, coating or practically any other process involved in producing high-value, high-performance manufactured parts.

Rolls-Royce’s Dr. Jamie McGourlay says the major challenge to advancing manufacturing technology in all of these areas has not been the lack of relevant innovation. Not at all—there are plenty of good ideas. Rather, a new “partnerships network” represents the vital element that has been missing in the past. Dr. McGourlay is the company’s partnerships network coordinator. He says the missing piece was an effective bridge for connecting the most useful ideas in manufacturing research to practical applications in production. While universities lack appropriate equipment for proving concepts at production scales, he says, the production facilities that do have that equipment lack open capacity—not to mention the time and attention necessary to fully explore new capabilities. As a result, neither the academic lab nor the production floor—nor both of these settings together—is quite enough for discovering and delivering innovation’s full benefits.

In fact, by one standard, the gap between these two settings is measurable. It’s about three levels. Dr. Steven Halliday is a Rolls-Royce manufacturing engineer and program manager. He describes a scale of readiness that he and other researchers use to characterize emerging manufacturing innovations. A new process or method at level 1 is little more than a drawing on a napkin. Level 3 describes an idea proven in a lab, and level 6 is an idea that has been demonstrated in a production setting. Level 9, the highest level, describes an idea so established that it is run in full-scale production at world-class performance.

A university laboratory, he says, usually struggles to take an emerging technology beyond level 4. A production setting is unlikely to touch a technology any earlier than level 7. Traditionally, Rolls-Royce and other high-value manufacturers have had little access to capacity for developing technology through the levels in between.

Now, that has changed. Since 2005, the company has been a partner in the Advanced Manufacturing Research Centre in the U.K.—which was conceived by the AMRC’s research director Professor Keith Ridgway of the University of Sheffield and by its commercial director Adrian Allen. This novel environment for applied research has recently grown to include a new 35,000-square-foot “Rolls-Royce Factory of the Future.” Now, Rolls-Royce is working with other partners to develop a manufacturing research network consisting of similar facilities elsewhere in the UK and other parts of the world.

The AMRC is a department of the University of Sheffield. Support comes from at least 60 manufacturing-related partner companies, including both users and suppliers of manufacturing technology. Much of the research here focuses on machining, with machine tool and cutting tool companies providing the AMRC with state-of-the-art equipment for this work. Dr. Halliday is just one of Rolls-Royce’s technical leaders engaged in research here, along with representatives from other OEM partner companies such as Boeing, BAE Systems and Messier-Dowty.

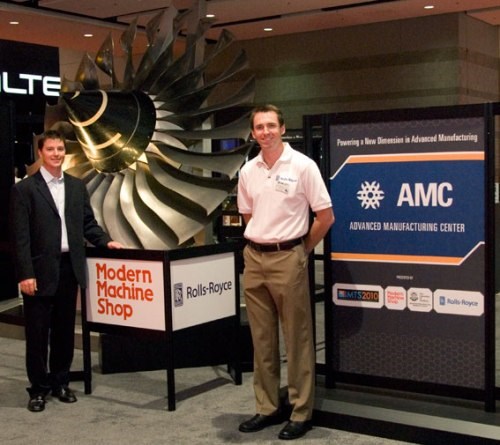

In the U.S., a similar facility will soon to be added to this network—the Commonwealth Center for Advanced Manufacturing (CCAM) in Petersburg, Virginia. Research associated with this facility is already underway, and the Center’s building is due to open in 2011. Brian Warner, Rolls-Royce lead for CCAM, says this facility shares various elements in common with the AMRC. One is partnership with leading universities in relevant fields—in this case, the University of Virginia and Virginia Tech. Another element (anticipated soon) is the commitment of various partner companies. Sharing resources across multiple organizations makes it possible to develop a committed and extensive research facility that no one company could justify on its own.

CCAM’s main distinction is its specialty. As the AMRC focuses primarily on machining, CCAM specializes in two areas: (1) coatings and surface engineering, and (2) manufacturing systems.

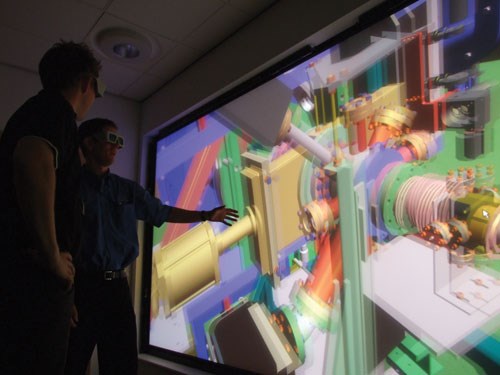

All research here—as at the AMRC, and at still other facilities in the U.K. and Singapore—is aimed at delivering manufacturing technology into production. For every research project, the “customer” is a production department facing a manufacturing challenge. The staffs of the AMRC and similar facilities work directly with OEM production departments to identify the manufacturing challenges that offer the most promise in terms of the potential cost or capability improvement in production. A given project might be small in scope—say, improving tool life in a particular operation—or it might be broad, such as introducing a new alloy and learning how best to machine it. In either case, the aim always relates to real-world manufacturing. Meanwhile, certain additional benefits often are also realized along the way.

Improved design is one. Mr. Warner points out that a better understanding of the manufacturing process almost invariably leads to a better understanding of the impact of design-related choices. Sometimes, the most important discovery of manufacturing research is not what machine or process to use in making the part, but instead what change to make to the part’s form or features in order to use existing production resources more efficiently.

Yet another added benefit relates to manufacturing development of a different sort. According to Dr. McGourlay, these research facilities that are now possible thanks to the partnership network provide an excellent way to both use and develop manufacturing talent. The company makes better use of experienced talent, and can better cultivate talent for the future.

In the case of experienced engineers, he says the network-developed facilities provide a venue for applying and refining that experience. Knowledgeable people get to use their knowledge to pursue more capable manufacturing methods.

Meanwhile, engineering graduate students get hands-on experience with modern and sophisticated production equipment—something that universities independent of such a partnership would not be able to provide. In fact, the network ultimately serves to make manufacturing itself more attractive. Students who are exposed to the facilities made possible through this network get to see just how compelling and valuable a career in advancing manufacturing can be.

Related Content

Shop Tour Video: From Garage Shop to Leading Aerospace Supplier

From repairing aircraft interiors to manufacturing medical implants, Superior Joining Technologies excels at CNC machining, TIG welding, laser welding, and NADCAP-accredited nondestructive testing. Discover how this Rockford-based company supports the aerospace industry through a combination of advanced technologies.

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreSolar Atmospheres Receives Northrop Grumman Approval for South Carolina Facility

All five Solar Atmospheres facilities are now an option for customers with Northrop Grumman requirements for vacuum heat treating.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)