Columns

Choosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

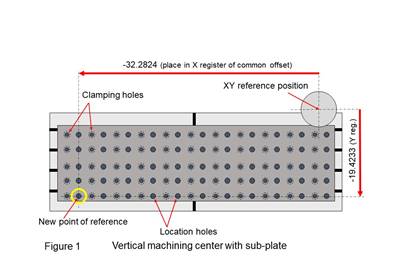

Read MoreThe Best Point of Reference for Program Zero Assignment Entries

Correctly specified program zero assignment and coordinate position values enable the CNC to determine how far to move the cutting tool during each positioning motion.

Read MoreThere's Your Waste, Shaw! An Argument for Shop Reinvestment

The fictional Don Walling had it right: Innovation and long-term success for machine shops requires investments in technology and people. Not just one, but both.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreHow to Optimize Operator Efficiency on Any Shop Floor

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.

Read MoreA Higbee Thread Milling Custom Macro

Higbee threads provide a full thread form at the very start of the thread. The sharp edge is removed during the machining process.

WatchCalling Home on a Portable Surface Gage

Today’s surface gages have a user interface that is just like a smartphone, and setting them up to make measurement requirements should be easy for the operator.

Read MoreAn American Manufacturing Story

For manufacturers that choose to move or keep production in the United States, what are the challenges and opportunities that motivate them?

Read MoreConsiderations for Properly Implementing Advanced Tool Materials

Many shops incorrectly assume advanced tools are plug and play. The tools may fit into existing tool holders, or even into the same shell mill pockets or turning pocket as carbide inserts, but that’s where the similarities end.

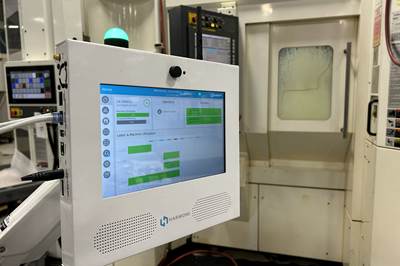

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreA Fond Farewell to My Additive Friends

In his final “Additive Insights” column, Tim Simpson reflects on how additive manufacturing has progressed in the last six years. Standards and software are two examples.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More