Columns

The Resurgence of 'Shop Class' in American High Schools

From the 1990s through the 2010s, most traditional “shop classes” disappeared from middle schools and high schools across the U.S. — one of the many issues that helped create today’s skilled labor shortage in metalworking and CNC machine shops. Here’s one solution that deserves more attention.

Read More4 Ways to Stop a Cycle to Allow Operator Intervention

Completely automatic operation should always be the goal, but there are situations that require operator intervention during the CNC cycle.

Read MoreCauses Are Complex: The Case for Choosing the Right Failures to Analyze

The nuance and complexity of failure in bearings is enough to illustrate the difficulty of failure analysis in general, and how much consideration this analysis deserves.

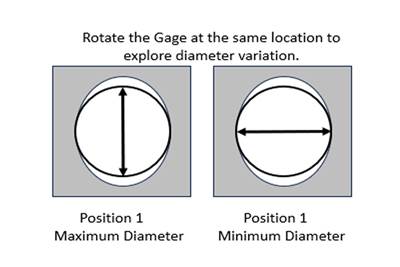

Read MoreTips for Anticipating Hole Conditions

When measuring an ID with an indicating plug gage, it is OK to slow down to learn more about the hole being measured and explore for extraneous conditions.

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreConsiderations for Adding CMM Capabilities to Your Shop

CMMs may provide simple efficiency gains, but if you look deeper, the machine unlocks more complex work for your shop.

Read MoreBehind Schedule Preparing for CMMC? You Are Not Alone.

The Department of Defense appears to be on track to begin a phased rollout of its Cybersecurity Maturity Model Certification assessment program by early 2025. What does that mean for defense contract manufacturers and suppliers?

Read MoreMachine Shops Move Beyond Metal Removal Rate as a Measure of Success

Metal removal rate is less of a defining factor for machining success than it once was. The reasons relate to changes in tools, processes, workpieces and machines.

Read MoreTroubleshooting Differences in Programming Methods, Machine Usage

Regardless of the level of consistency among machines owned by your company, you probably have experienced consistency-related issues. Here are some tips to help solve them.

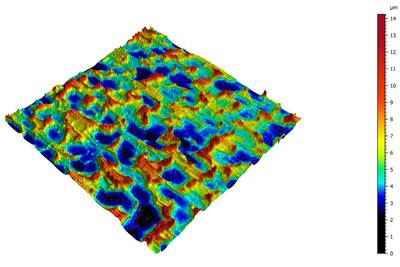

Read MoreMoving from Contact to Noncontact Surface Analysis

2D measurement systems check specific lines for roughness quality, while a 3D surface analysis provides assurance for a broader area — which can avoid costly process disruptions and bonding failure.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read More