Columns

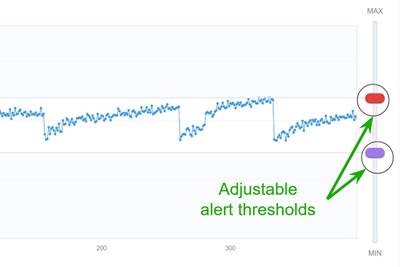

The CNC Reveals its Secrets

Machine monitoring becomes a platform for predictive maintenance without requiring extra sensors.

Read MoreNew Ways We Cover the Choices and Challenges of Machining

Recently added: a new resource for machining-related process challenges, and a new video series appreciating the distinctiveness of different shops.

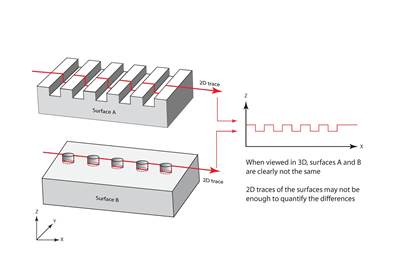

Read MoreWhen Manufacturers Should Use 3D Measurement for Surface Finishing

Two-dimensional (2D) surface profiling systems are the standard for quality assurance in manufacturing, but some applications demand 3D measurement systems.

Read More5 Things CNC Operators Must Know About Sizing Adjustments

For CNC operators, sizing adjustment is an essential skill. Keep these points in mind when training new CNC users.

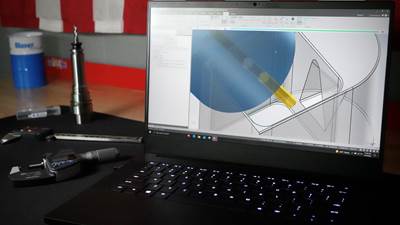

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreIs Additive Freeing Designers or Aiding Manufacturers?

A shift toward maximizing AM benefits for manufacturers, not only product designers and process engineers, will help AM take off.

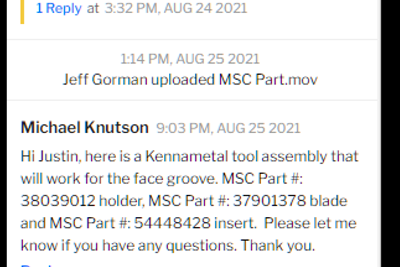

Read MoreThe Secure Channel: ITAR-Compliant Link Connects Machine Shops and Machining Advisors

Confidentiality concerns plus a shortage of experienced staff can leave shops isolated from expertise. How a system developed by two companies might change access to specific, real-time advice on machining challenges.

Read MoreWhat Manufacturers Need to Know About Metrology

As manufacturing technology advances, measurement processes evolve to stay one step ahead.

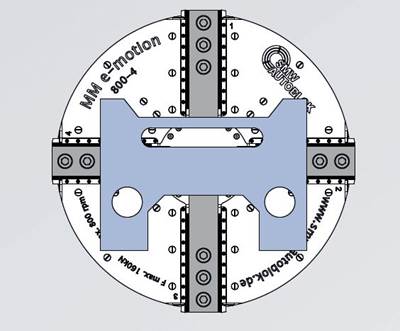

Read MoreWireless Couplers Work Wonders for Workholding

Possibilities range from individual control of chuck jaws and tombstone fixtures to more reliable robots.

Read MoreReducing Machine Cycle Times Both In and Out of the Cut

Increasing automation means setup times are lower than ever. How can shops optimize cycle times to match and win more business?

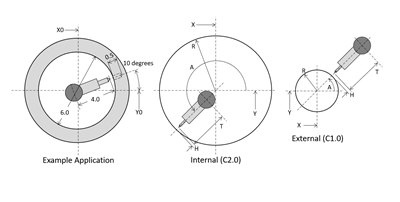

Read MoreHow to Drill Holes With a Right-Angle Head

Drilling with a right-angle head in a machining center spindle can be tricky – doubly so if the hole must be peck-drilled. A custom macro and careful attention to positioning help ensure smooth production.

WatchCan Transparency Bring More Efficient Sourcing?

A resource that aims to be free for machine shops asks detailed capability information so parts can be matched to producers, and OEMs can target RFQs to shops that are ready to run the work.

Read More