Choosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Share

Manufacturing a groove on a turned part is usually easier than inspecting it. Select the right cutting tool, set the part program and — in an instant — you’re done. But good gaging practice is a must because of the critical functional role played by grooves for seal rings and retainer rings. There are many different gage types from which to choose, and because inside grooves tend to be more difficult to measure than outside grooves, we’ll examine inside groove gages more closely.

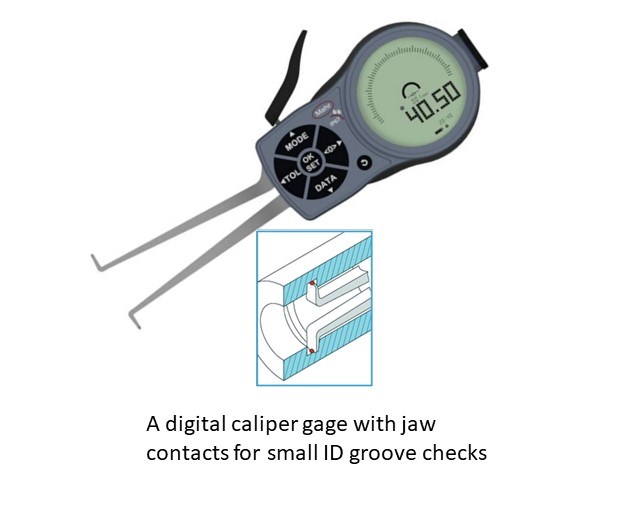

The most basic and universal groove gage is a digital caliper gage with jaws specifically designed for measuring internal grooves. There are two versions of this type of caliper gage: the “Swiss Army knife,” or universal caliper, and the dedicated specialty caliper.

The universal caliper is a great tool, often found in the incoming inspection area where versatility and various measuring capabilities are required. While the caliper itself looks standard, it can employ several different tips for the jaws. Different tips serve different tasks, but there are sets for various groove widths, depths and either inner diameter (ID) or outer diameter (OD). Usually, these may be treading into the jaw so that if the standard tips in the kit do not meet the requirements of the task, one can make up some custom tips for the application — thus, the name universal caliper.

Then there are families of calipers dedicated to measuring internal or external grooves. These have standard configuration jaws, as specified by the manufacturer. For many applications, they may be just the ticket for the task at hand. And calipers with digital capabilities and data output fit right in when documentation of the process is required. The main limitation with these gages is their ability to get into very small holes since the size capability is related to the size of the measuring jaws. The other limitation could be the resolution capabilities of the caliper themselves.

Inside-measuring swing-arm gages, or caliper gages, are general-purpose instruments that may be applied to a wide range of inside dimensions, including inside grooves. This version of caliper gage can get into ID grooves starting at 0.2 inches (5 mm), while larger ones can measure through their entire retraction range through over 3 inches (75 mm). These gages can therefore measure features where variation is expected to be large and can measure variably sized parts without adjustment.

Today, most of these swing-arm caliper gages have gone digital, offering the same long measuring range and digital data sharing as found in most digital calipers. Therefore, they offer similar versatility, sometimes at increased resolutions. These do take a bit of operator skill to use since the groove may need to be explored radially and axially to find the true diameter. But with a little practice, an experienced user can get good results and provide capabilities for some very small requirements.

Finally, bench-type ID/OD comparators can measure inside and outside grooves if fitted with special contacts. ID/OD comparators offer the highest potential accuracy since they are comparison-type gages and evaluate the measured dimension to a known master. Also, because the bench gage is usually self-centering and can be a hands-off measurement, they provide the best diameter results and allow the part to be rotated to explore the groove for minimum or maximum readings.

The limitation with these types of gages, though, would be to measure very small parts as the jaws need to be constructed to get into the small groove while having enough retraction built into the gage to enter the bore on the way to the groove to be measured. Thus, these gage types are typically used for grooves larger than 1 inch (25mm) from the mouth of the bore.

Inside-diameter groove measurements can be a bit of a challenge, but with the right tools and contacts, they can be dealt with and enable the operator to get the results needed.

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHelp Operators Understand Sizing Adjustments

Even when CNCs are equipped with automatic post-process gaging systems, there are always a few important adjustments that must be done manually. Don’t take operators understanding these adjustments for granted.

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More