Columns

How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

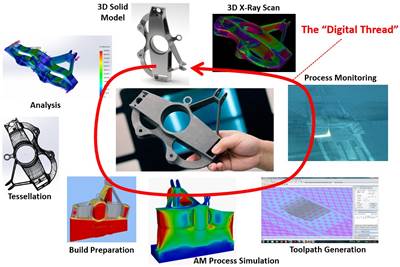

Read MoreGo Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.

Read MoreThe Tension Between Current and Coming Markets Cannot Be Resolved

A healthy business needs to keep that tension alive. That observation is one of several I have come to through my role during the past several years.

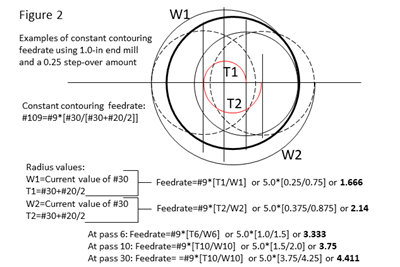

Read MoreA Spiral Milling Custom Macro Using Constant Contouring Feedrate

Helical milling or “spiral” milling are helpful when machining a circular pocket that is much larger than the milling cutter diameter.

Read MoreTeam Unity – the Tightrope Walk for Corporate Culture

Finding your place in an organization doesn’t always mean falling in line. But creating a culture of continuous improvement means fostering unity among independent thinkers.

Read MoreBring the Surface Finish Check to the Part

Dedicated handheld gages can assist the operator in making critical checks.

Read MoreStrategies for Expanding a Shop the Right Way

It’s very easy to get paralyzed by all the directions you can go when upgrading a shop, but breaking this decision into its simplest forms can help curb future buyer’s remorse.

Read MoreDoes Metal Additive Manufacturing Belong in a Machine Shop? The Answer Is Mixed

Machining is a necessary capability for metal part production through 3D printing, but succeeding with metal AM demands a role and procedures much different from those of many machining providers.

Read MoreSaving Time and Money on the Shop Floor with AM

The ways additive manufacturing is presented sometimes miss the most practical and valuable ways it can be used.

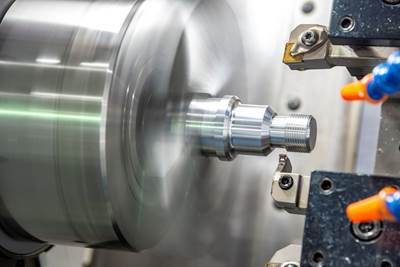

Read MoreImprove CNC Productivity by Addressing Three Production Issues

To boost a CNC machine’s productivity, prioritize improvements to machine setup time and production runtime.

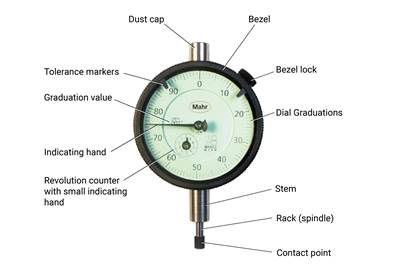

Read MoreReading What the Dial Indicator Is Saying

Dial indicators provide good value for their resolution. With a glance, one can quickly determine if the part is larger or smaller than the master setting and by a degree of how much.

Read MoreSolving Process Issues With a Detail-Oriented Approach

It is essential for a machinist and a shop to have the discipline to pause a process and reassess when encountering issues, even when schedules are tight.

Read More