Columns

Modern Bench Amplifiers Offer More Evaluation Capabilities

Today’s electronic gaging amplifiers can do more than take comparative measurements. New features have become common, opening possibilities for machinists and manufacturers.

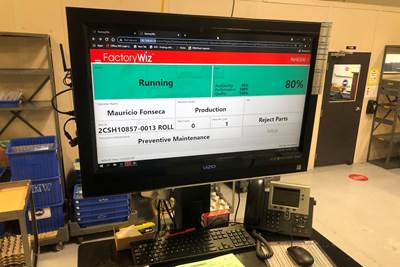

Read MoreMonitoring Machine Tools? Don’t Discount DNC

Networks that feed part programs to shopfloor CNCs can double as a foundation for pulling data from them.

Read More5 Ways to Simplify Tasks for CNC Newcomers

Manufacturers can easily train new CNC users by simplifying tasks. Learn how to simplify CNC tasks for new hires in this CNC Tech Talk.

Read MoreHow to Make a Surface Plate Into a Gage

Surface plates provide a stable reference surface on a large scale, enabling multiple gage setups, but they can also be turned into a gage themselves.

Read MoreRobots Get a Ride with CNC Machine-tending AGVs

Mobile machine tenders prove that “automation-ready” is a state of mind.

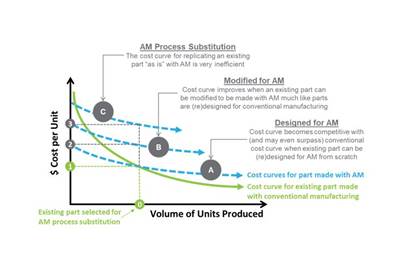

Read MoreThe Challenge with AM Process Substitution

Making a one to one replacement of a part with AM is rarely cost-effective. Approaches like MFAM can improve the cost curve for AM, as Tim Simpson illustrates.

Read MoreGuarding Against Cyberattack Is a Drain on Machining Capacity

The Colonial Pipeline shutdown was a warning about the dangers of malicious use of data networks. However, as the full value of Industry 4.0 becomes apparent, isolating CNC machine tools from networks will be seen as an increasingly costly way to protect manufacturing from threats.

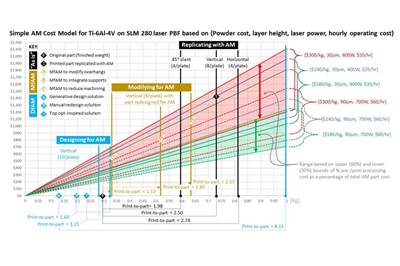

Read MoreBalancing MfAM and DfAM for Metal Additive Manufacturing

For viable metal AM, users must balance design for additive manufacturing (DfAM), modifying for additive manufacturing (MfAM) and cost per kilogram.

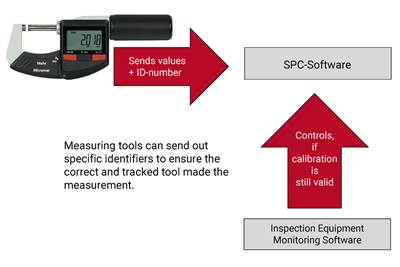

Read MorePreparing SQC For Machinists and Future Requirements

The current complexity of machines means machinists are already busy — assigning them new, expanded SQL duties (such as gage identification) will require gages and processes to prioritize accessibility.

Read MoreIs Wireless Data Collection a Cultural Choice?

Untethered digital inspection tools are easier to justify for those who are willing to hold themselves accountable and improve for improvement’s sake.

Read MoreChallenges Reveal Value and Vulnerability of Small Machine Shops

Small business ownership is conducive to the kind of oversight and commitment that serves machining well, but small business also relies on the support and commitment of enterprises around them.

Read MoreCalling Custom Macros Through Modal Commands

While G65 does not enable users to simply and easily carry out Custom Macros in multiple locations, G66 and G66.1 provide modal solutions for doing so.

Read More