The Secure Channel: ITAR-Compliant Link Connects Machine Shops and Machining Advisors

Confidentiality concerns plus a shortage of experienced staff can leave shops isolated from expertise. How a system developed by two companies might change access to specific, real-time advice on machining challenges.

Share

Does asking for help make us vulnerable? If a machining business is the one doing the asking, the answer is very likely yes.

In the business of contract machining, we have now reached a point where the speed and specificity of technical expertise are being impeded by the confidentiality concerns of machining customers. Confidentiality is a challenge to competitiveness and quality. This knot was tied gradually — here is how we arrived at this state:

1. Experienced, well-versed machining experts were more common in shops a generation ago. Today these people are stretched thin, and the demands on their attention make it hard for them to keep current with developments such as new tool options.

2. Maintaining confidentiality has increasingly become a part of the culture of machining. Part of the reason is the increasing value of being first to market with new product designs, and part of it is institutionalized information control through compliance with systems such as ITAR.

3. While the logical response to point 1 is to reach outside the organization for expert advice on machining challenges, the constraint of point 2 means the shop has to be guarded about disclosing the challenge. Emailing a customer’s CAD drawing to ask for advice in machining a given feature is dangerous; who else might see that email? Thus, process efficiency and data security are competing goals.

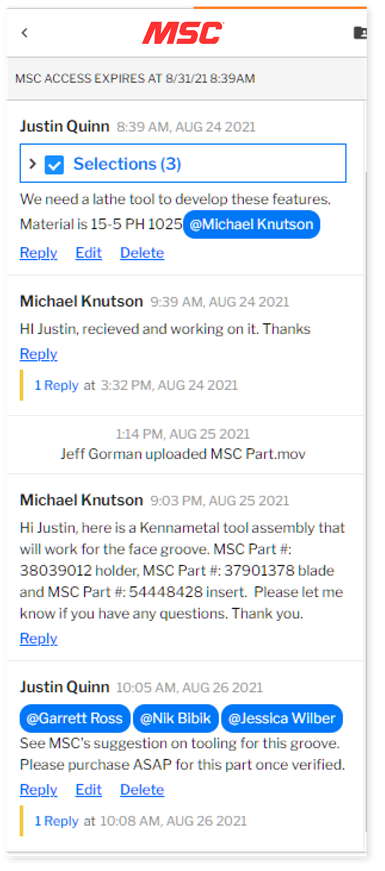

This conversation aimed at finding the right tooling for a challenging feature was facilitated by a closed digital channel allowing confidential part files to be shared. Photo: MSC and Paperless Parts.

Paperless Parts and MSC Industrial Supply Co. both see this. Paperless Parts is a pricing engine for machined parts that helps shops quote jobs more efficiently and quickly. MSC is the wide-ranging distributor of many consumables used in machining, notably cutting tools from many providers. The two companies together have launched “TechMate,” essentially a secure channel between the Paperless Parts software and MSC. The software user seeking advice related to a quote can freely share relevant resources with an expert at MSC without information ever leaving an ITAR-compliant environment. (Here is Paperless Parts’ own description of the capability.)

In separate conversations, I recently spoke with Paperless Parts CEO Jason Ray about this, and with Jamie Goettler, MSC’s senior director of metalworking sales and innovation. Ray sees TechMate as a data security advance; Goettler sees it as a response to the skills gap. They’re both right.

Paperless Parts has so far introduced this free resource to 1,000 of its users. In each case, the user and MSC both have complete access to the software’s viewer as a communication aid, because “communicating what’s going on using screen shots is pretty hard,” Ray notes. An early success: Denver-area Focused on Machining received an RFQ for a complex part that seemingly would have taken the shop too long to run cost-effectively. The reluctance to seek an outside opinion in this case related less to secrecy, and had more to do with the time and tedium the back-and-forth communication might entail. By using the viewer and the open channel, Focused on Machining president Justin Quinn sent MSC the part model with the concerning geometry highlighted. In a few hours, an MSC advisor responded with tooling suggestions that made the job viable. Focused on Machining won what proved to be a $57,000 order from an RFQ that came close to being a no-quote.

Goettler says COVID-19 helped accelerate the development of this system. Getting metalworking experts into shops was a challenge before the pandemic. Now, covid has made everyone more accepting of virtual communication. Expertise sharing can move more seamlessly as a result. MSC now has metalworking technology advisors who are devoted to fielding TechMate inquiries. Additionally, users have the option to send their queries to their local MSC representatives, and many choose to do this.

Two other interesting possibilities Goettler sees describe how much farther the expertise-sharing might go. Given the direct open channel plus the secure link for sharing information, shops potentially have much more ease and freedom in the information they might share, and MSC can go further in the information it might ask for.

“We use MSC Millmax software to analyze vibrations in a machine’s setup to identify optimal cutting speeds as well as axial and radial depths of cut, and we can do this analysis based on the sound of the machine cutting,” he says. That suggests one possibility: Shops could use the ITAR-compliant channel to share the very sound of their cutting, so experts on the other end can diagnose concerns related to chatter.

The other possibility is this: This system does not have to be used only by job shops, Goettler says — that is, only by shops doing quoting. As remote access to expertise becomes widely accepted, he expects all manner of shops to take advantage of it, at all stages of the work.

He says, “An OEM or production shop that has been running a part for a long time might tell us, ‘To increase capacity, we need to machine faster — how can we cut 5 seconds from cycle time?’” The system is now being built that makes it safe, as well as natural, to draw on outside expertise in facing machining challenges such as this.

Related Content

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)