High Speed Air Spindle Example 4: Hand Deburring

Just a light touch is required using this device as its high speed does the cutting. Combined with low vibration and weight, this reduces the risk of stress injuries to operators.

WatchWanna Give MQL a Try?

If you own a Haas machine, here’s your chance to give minimum quantity lubrication a try.

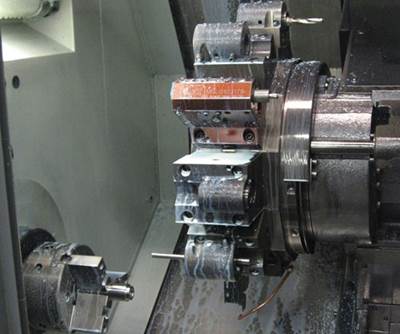

Read MoreTop Shops 2011: High Tech Turning

Advanced Swiss-type-lathe technology enables this shop to create intricate components for complex medical, electronic and military applications.

Read MoreTop Shops 2011: Millat Industries

This shop invests in advanced CNC machines, CAD/CAM packages, CMM inspection systems and robotics to keep its value-added services cost effective for its customers.

WatchSee How You Stack Up

“Top Shops” benchmarking data sheds light on what it takes to be one of the nation’s leading machining businesses.

Read MoreTop Shops 2011: K Tooling

K Tooling combines CNC machining with in-house fabricating, plating and painting capabilities to effectively take turnkey projects from CAD designs to final products.

Read MoreTop Shops 2011: Altech Machining Inc.

Although this shop’s specialty is production CNC turning, its secondary milling, honing (or lapping) and grinding capabilities enable it to succeed in producing accurate hydraulic valve components and assemblies.

WatchTop Shops 2011: Air Flow Research

One of our 2011 Top Shops, this manufacturer of high-performance cylinder heads has a long history of applying five-axis machining to create complex internal features.

WatchMachining with the Environment in Mind

It’s safe to assume that most shops recognize the importance of being environmentally responsible. However, benchmarking data suggests that the effort shops put into both recycling and reducing energy consumption varies.

Read MoreTop Shops 2011: C&R Manufacturing Inc.

C&R Manufacturing specializes in creating precision turned parts using CNC lathes with live tooling. Combined with the use of bar feeders, automatic gaging and robotic part handling, this enables the shop to generate intricate workpieces sans human intervention.

Read MoreTop Shops 2011: Hyper-Tech

This shop uses CNC turning, milling, gear cutting, ID and OD grinding, honing and broaching to be a done-in-one supplier of machined parts.

Watch

.jpg;maxWidth=400;quality=70)