Share

Sometimes a market opportunity spurs a shop to add specialized equipment to pursue work in an industry it hasn’t served. Other times, the shop already has the capacity in place to effectively support such efforts. The latter was the case for Bley LLC, located in Elk Grove Village, Illinois.

A few years ago, Bley started actively pursuing work for the wind energy industry, which has shown signs that it’s about to take off here in the United States. Wind turbines require various hefty, precision-machined components. Because Bley’s focus has been supplying medium- and large-scale machined parts as heavy as 30,000 pounds to a variety of other industries, it already had the appropriate machining capacity in place for new wind-turbine business.

Today, Bley machines components such as torque arms, planet carriers and gearbox housings for wind-energy customers. Much of this work is performed on the shop’s nine CNC horizontal boring mills with W-axis heads, which are ideal for these types of components. Bley also has large VTLs for big parts that require turning work as well as CMMs that can accommodate sizeable workpieces as part of its accredited ISO 9001:2008 and AS9100:C quality systems.

Some have projected that in 15 years, wind turbines will supply 20 percent of this country’s electricity needs. If that’s the case, Bley, in addition to other shops that posess large-scale machining capability, is well-positioned to take advantage of this emerging market and any others that require big, accurately machined parts

Company Profile

With a history that can be traced back to 1923, Bley LLC is a manufacturing company that provides precision machining, engineering, machine building, assembly and fabrication services. Located in a 65,000-square-foot, climate-controlled facility, the shop manufactures components for a range of industries in prototype or high-production volumes. From start to finish, Bley LLC quotes parts and engineers a manufacturing process to meet or exceed customer part specifications. These specifications are managed via an integrated system that tracks all aspects of the process from order entry to pick-up and delivery of the product when needed.

With the innovative use of supervisory control and data acquisition (SCADA) industrial control technology, Bley LLC personnel always know a workpiece’s location and its stage of production. This level of traceability enables the shop’s highly trained staff to instantly identify and fix bottlenecks and respond to changing customer demands.

Bley LLC’s employees are the cornerstone of its success. Its machinists and operators have the technical skills and practical experience to manufacture components to the tight tolerances that are typically required. An emphasis on training ensures that all employees maintain their edge and foster success in their careers.

The video above explains the growing opportunities in wind energy for shops like Bley LLC that have large-scale machining capability. Two prime wind turbine components the shop machines on its HMCs are planet carriers and torque arms.

Key Personnel

- Erich Bley, Owner

- Krishna Rajagopal, Owner

Products/Services

End Markets Served

- Aerospace

- Alternative Energy

- Defense

- Heavy Transportation

- Medical

- Mining

- Oil & Gas

- Nuclear

- Packaging

Workpiece Materials Commonly Machined

- Aluminum

- Grey Iron

- High-Temp Alloys

- Inconel

- Stainless Steel

- Titanium

Related Content

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreCreating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

Read MoreTop Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreRead Next

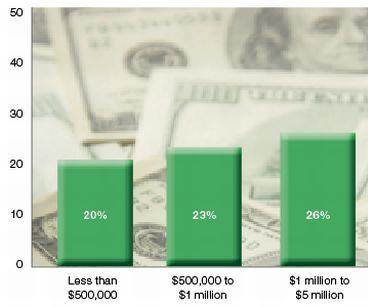

See How You Stack Up

“Top Shops” benchmarking data sheds light on what it takes to be one of the nation’s leading machining businesses.

Read MoreEach Shop’s One Big Thing

Top Shops tend to be good all around, achieving excellence or better-than-average ability in almost all of the activities or processes they perform, yet several technologies or strategies stand out as the most influential.

Read MoreMachining with the Environment in Mind

It’s safe to assume that most shops recognize the importance of being environmentally responsible. However, benchmarking data suggests that the effort shops put into both recycling and reducing energy consumption varies.

Read More

.jpg;maxWidth=300;quality=90)