Top Shops 2011: Hyper-Tech

This shop uses CNC turning, milling, gear cutting, ID and OD grinding, honing and broaching to be a done-in-one supplier of machined parts.

Share

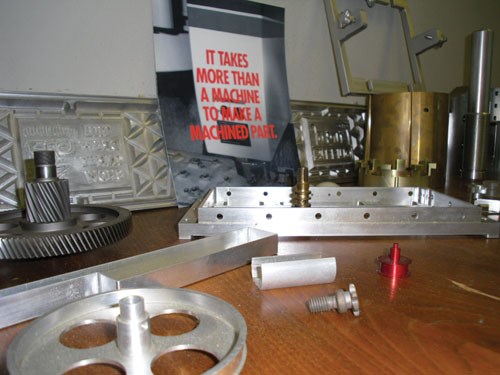

More than an ordinary machine shop, Hyper-Tech offers turning, milling, gear cutting, ID and OD grinding, honing and broaching all on the latest CNC equipment. This enables it to maintain high quality standards throughout the entire manufacturing process.

Hyper-Tech is dedicated to producing parts that meet today’s tough acceptance standards, and its quality control system is designed to meet or exceed most aerospace requirements. Its machinists have gone through rigorous journeyman training. They go back to school for continuing education on the latest technology, including CNC and CAM programming and the newest quality-control methods. The shop designs and manufactures mechanical assemblies, prototypes and runs production-volume lots. It works with a vast array of metals from aluminum to zinc as well as plastics.

Related Content

-

Finding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

-

2024 Top Shops Honorees Announced

Modern Machine Shop Recognizes Excellence in Manufacturing with Annual Award

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.