Minimizing Turnaround Times for Big Parts

The key to success (and the primary challenge) for any job shop is minimizing turnaround time for non-repeating work. This Indiana shop shares some of its strategies for reducing lead times for the various large-scale jobs it encounters.

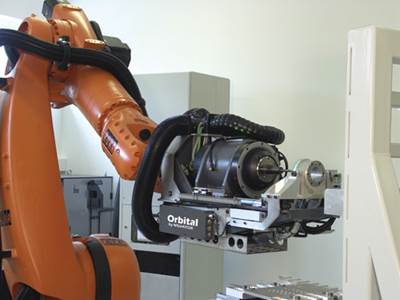

Read MoreEffective Hole Making Via Robotic Orbital Drilling

New technology may enable robotic drilling to be more commonplace in machine shops by overcoming the issue of limited robot rigidity.

Read MoreFree Webinar: Secrets of Cost Savings through CNC Innovation

CNC innovation can deliver the lowest Total Cost of Ownership for production equipment. Find out how on June 21 during a free webinar presented by Fanuc FA America and “Modern Machine Shop.”

Read MoreHeavy Turnout for Innovation Days

Approximately 1,600 people attended the recent Innovation Days event at DMG/Mori Seiki, which featured more than 30 milling, turning and multitasking machines.

Read MoreWhat’s in a Code?

You’ll start to encounter two-dimensional matrix codes like this more frequently. Learn how your shop might benefit from them.

Read MoreSteady as She Goes

Machine shops are inventive operations. Learn how one uses a steady rest in a different way on one of its two-turret CNC lathes.

Read MoreMicromachining and Flat-Screen TVs

A Pennsylvania shop has benefitted by developing an effective micromachining strategy for hard tooling components. Learn more about this as well as the interesting incentive program it’s implemented.

Read MoreLook for the Codes

Two-dimensional matrix codes are being used for everything from marketing campaigns to positioning tool presetters to linking print magazines with bonus online content. Consider how you might use them.

Read MoreMulti-Wheel Grinding of Big Gears

New profile grinding technology is said to significantly improve productivity for big gears by grinding four tooth flanks simultaneously.

Read MoreA New Approach to Tool Presetting

This non-contact presetter has a number of design elements that enable it to perform effectively on the shop floor. It looks and operates differently than other presetters currently available, too.

Read MoreIs Now the Time for a Shopfloor CMM?

You’ve integrated more effective, efficient machining equipment to improve throughput. Perhaps now it’s time to take a closer look at how part inspection impacts your overall process.

Read MoreAn Innovative Way to Use a Steady Rest

This shop found a way to modify one of its two-turret CNC lathes so that a tricky aerospace component could be properly supported for critical operations.

Read More

.jpg;maxWidth=400;quality=70)