MMS Blog

Five-Axis Machining Expands Its Range

Advancements in 5-axis machines, controls and software have made this technology so productive and easy to use that it can now benefit a much broader range of shops.

WatchPodcast: Shaping the Industrial Buying Process

Dave Necessary, Gardner Business Media's director of strategic engagement, shares key insights from 2020 Industrial Buying Influence Report on Industrial Strength Marketing podcast.

Read MoreTrained in a Day, Automated Inspector Performs Faster than Humans

Using recent technological innovations in robotics, optics, edge computing and artificial intelligence, MusashiAI has developed an automated visual inspection system that could free a significant portion of the automotive workforce to perform easier, more interesting tasks.

Read MoreAutomating the Indicator Calibration Process

Eliminate human error when calibrating precision hand tools by leveraging modern vision systems.

Read MoreProShop DME Streamlines Job Shop Operations

Illinois-based job shop 3D Industries had difficulty managing its communication and data, a trouble that disappeared after the company began using Adion Systems’ ProShop DME.

Read More3D Printing, Generative Design Put This EV on a "Diet"

Redesigning and consolidating the components of Arcimoto's Fun Utility Vehicle (FUV) will bring this small electric car into the realm of micromobility. More in a recent episode of The Cool Parts Show.

Read More20 Years of “The Z Axis”

Peter Zelinski notes the 20-year anniversary of his monthly column for Modern Machine Shop, offering reflections on writing this column for machining leaders and professionals over the span of two decades.

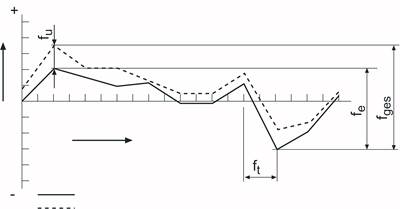

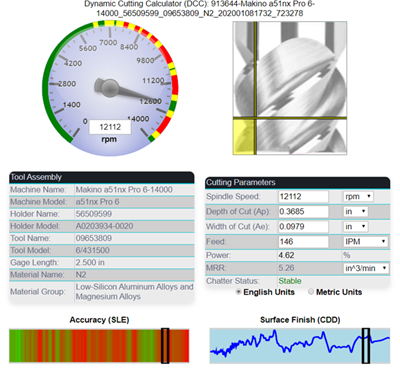

Read MoreHow Machine Tool Dynamics Could Become a U.S. Supply Chain Strategy

A collaborative agreement being overseen by the U.S. Department of Energy involves a deceptively simple test — a test that could radically increase throughput of the United States’ existing base of CNC machine tools.

Read MoreHow to Choose the Best Drill Type for Your Next Job

Five questions to ask when deciding between solid carbide drills or replaceable insert.

Watch3 Ways to Improve CNC Utilization Without Sacrificing Safety

Operator safety is the most important consideration when improving CNC machine utilization.

Read MoreCutting Data, Indexable Inserts Optimize Fine Boring

By using digital technology and optimized indexable inserts from Big Kaiser, Schmauser Müller Metalltechnik has increased its process reliability and efficiency in fine boring applications as well as improved tool life.

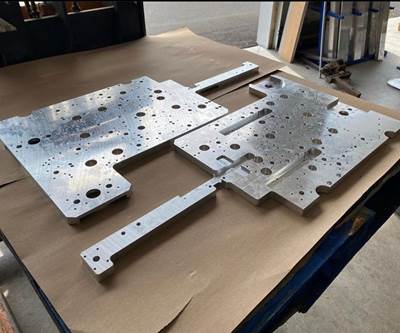

Read MoreMachining a Complex Part in a One-Man Shop

Feature recognition and efficient workholding let this shop cost-effectively produce an intricate part that was bigger than the machine tool's travels.

Read More