MMS Blog

Monitoring the State of Tool Monitoring

Digital technology that enables tool changes to be triggered by data-driven predictions of tool wear rather than part counts also is opening the door to other opportunities for optimizing production. A look at in-the-field applications shows that advanced tool monitoring is a step toward plant-wide digitalization.

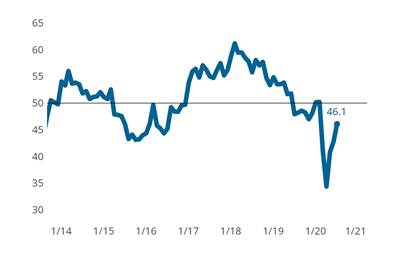

Read MoreJune 2020 A Strong Month for Machine Tool Orders

The month-over-month rate of contraction in machine tool unit and dollar orders slowed sharply in June. The annual rate of contraction may be near or at a bottom.

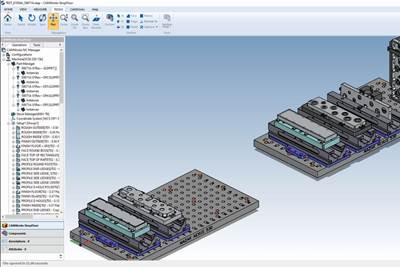

Read MoreIntegrated CAM Software Automates Data Transition From Engineering to Production

By switching to CAMWorks software, Decimal Engineering was able to boost its throughput and quality while saving time and money.

Read MoreGrowing a Job Shop into a Full-Service Manufacturer

By maximizing employee satisfaction, adding fabrication and other services, and always keeping open machine capacity, Square Deal has grown from a seven-person job shop to a full-service manufacturer that employs hundreds.

Read MoreMetalworking Business Activity Reports Additional Slowing Contraction

July data extends the slowing contraction trend initially reported in May.

Read MoreA More Affordable Approach to 5-Axis Large Part Machining

Shops that machine large aluminum parts don’t have to pay millions of dollars for a machining center just to get the work envelope they need. There is a more affordable alternative, and it’s manufactured in the USA.

WatchPortable Surface Gaging in a Production Environment

Handheld portable surface gages are easy to use. But that doesn’t mean there aren’t challenges when scanning hundreds or even thousands of parts.

Read MoreHow To Reference Custom Macro Variables by Name

FANUC now enables CNC users to reference custom macro system variables by names in addition to hard-to-remember numbers. Here’s how.

Read MoreAre Employees Really Replaceable?

Although an individual might consider themselves to be replaceable, an organization should not see their employees that way.

Read More5 Hard Lessons from a 28-Year-Old Startup Machine Shop Owner

Good fortune and years of long working hours have both figured into the success of this young shop, which became its founder’s sole employment starting last year. The shop owner shares his story.

Read MoreMachine Monitoring Circles Back to Basics

Deeper insights from more varied data are no replacement for manufacturing fundamentals.

Read MoreHope Is an Asset: Here Are Machine Shops Following Clear Visions for the Future

A simple strategy offering a clear aim to hope for is particularly valuable during a disruptive time. Recently posted articles offer examples of shops following clear ideas for the way ahead.

Read More