MMS Blog

Multitasking Machining Equipment: Now the New Normal

Equipment that can turn, mill and more is quickly becoming the standard in metalworking technology. These machines can produce increasingly complex parts in a single setup yet are easier operate than ever before.

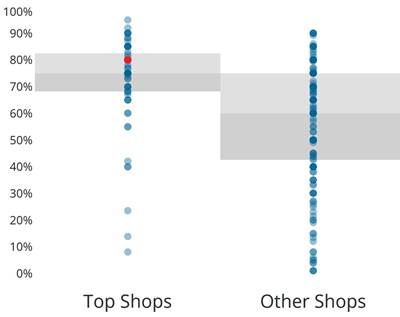

Read MoreAn Introduction to Modern Machine Shop's Top Shops Program

Presented by Gardner Intelligence, an annual benchmarking program helps CNC machining businesses specifically evaluate and improve performance.

Read MoreWorkholding Considerations for Five-Axis Machining

Five-axis workholding isn’t just about applying technology; it’s also about applying a different mindset.

Read MoreNew Educational Series from Additive Manufacturing Media

Additive Manufacturing Media is releasing AM InDepth, a series on 3D manufacturing, as a part of IMTS Spark.

Read MoreSolid Construction and Fourth Axis Are Highlights of Shop’s Newest VMC

A vertical machining center with a fourth axis from Kent USA enables Mega Industries LLC to serve national laboratories quickly and accurately.

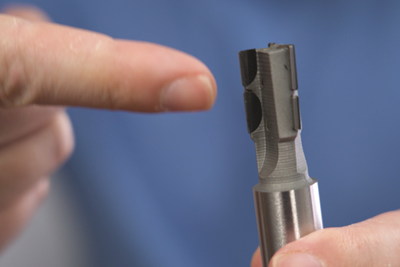

Read MoreVideo: 3D Printed Tool Illustrates the Impact of Additive Manufacturing on Machining

Is AM an aid to machining? A competitor? It’s both. The Cool Parts Show looks at a milling tool design made possible by 3D printing.

WatchVideo: Topology Optimization in Action

What is topology optimization, and how does it work? See the process for lightweighting a legacy part step-by-step using this design strategy in the video in this blog post.

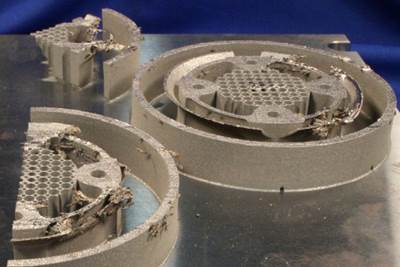

WatchThe Harsh Realities of Additive Manufacturing

Now is the time to start talking about what is really holding additive manufacturing back.

Read MoreAdditive Manufacturing Media Kicks Off Season Three of "The Cool Parts Show"

This hit web series continues with more episodes about industrial 3D printing.

Read MoreVideo: Starting Your Own Machine Shop — the Rewards and Challenges

The owner of Dan’s Custom Machining on the decision to go full-time with his machining business, advice for future shop owners, and whether buying machine tools is fun.

WatchSometimes No-Quoting RFQs is Essential for Efficiency

Accepting only RFQs that work toward a company’s goals and learning how to manage those efficiently can build better businesses and customer relationships.

Read MoreCentralized Filtration Key to Company Growth

By investing in a Transor Filter System, Advanced Tooling Inc. was able to immediately improve cycle times and gain a consistent cutting environment.

Read More