Share

Hwacheon Machinery America, Inc.

Featured Content

View More

The Fun Utility Vehicle (FUV) is a lightweight, fully electric car designed for right-sized transportation. The 1,300-pound vehicle “lost” 12 pounds in 30 days thanks to generatively redesigned parts enabled by 3D printing (the pink suspension components seen here). Photo Credits: ParaMatters

“There’s a giant disconnect between what a car can do and how we actually use them on a daily basis,” says Mark Frohnmayer. “And that disconnect creates a massive amount of inefficiency.”

Although most cars can carry five to seven people and travel hundreds of miles, the majority of trips are local and move just one or two people at a time, he explains. Most of us are driving around more car than we need to be, using more fuel and occupying more space than is truly necessary.

Frohnmayer’s proposed solution to this problem? Don’t change drivers’ behavior, but give them a vehicle better suited to the driving they actually do. Frohnmayer’s company Arcimoto has developed just such a car, the Fun Utility Vehicle (FUV). Rather than two or three rows of seats, the FUV is built to carry only two passengers. It is unenclosed and has no trunk — just a cargo locker that can hold at most a couple of shopping bags. Intended for small, local trips, the FUV is a fully electric vehicle and has a range of about 100 miles on a single battery charge.

But although the FUV looks quite different than a conventional car, it is still made with many conventional manufacturing techniques such as machining, metal forming and welding. When the vehicle went into full production last year at Arcimoto’s factory in Eugene, Oregon, Frohnmayer still wasn’t completely satisfied with the design. At 1,300 pounds, the FUV weighs considerably less than a conventional coupe, but he wondered if it could be made lighter still.

A chance meeting with Avi Reichental, cofounder of design software company ParaMatters, proved that it could. After test driving the FUV, Reichental commented to Frohnmayer that the car was “really fun, but it could use a diet.” He proposed utilizing ParaMatters’ generative design software to reimagine some of the car’s components, and together they set a target to reduce the FUV’s weight by 200 pounds, bringing it into the “micromobility” class of vehicles.

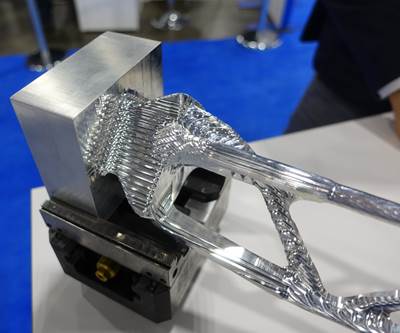

The original steering knuckle (right) is a nine-piece weldment weighing about 6 pounds. The redesigned component (left) weighs about 3.7 pounds and was 3D printed as one piece.

The initial project focused on the FUV’s steering knuckle (pictured above), rear swing arm and two upper control arms. Components were consolidated and redesigned using ParaMatters’ CogniCAD cloud-based software, and either directly 3D printed in metal or investment cast with 3D printed patterns. The new components resulted in a weight savings of about 12 pounds, achieved in just 30 days.

Co-host Pete Zelinski and I discuss these early successes in lightweighting the FUV, as well as what generative design will mean for the future of sustainable transportation, in a recent episode of The Cool Parts Show (a video series focused on innovative 3D printed parts). Watch to learn more and see the FUV in action:

(For a full transcript of this episode and additional detail, visit AdditiveManufacturing.media.)

Related Content

Ford Partners With Rockwell Automation to Advance EV Program

The companies will jointly collaborate on assembly tooling designs and architectures that will increase speed to market.

Read MoreSunnen Products Company Partners With Hendrick Motorsports

The partnership puts the new Sunnen SV-series honing machine in the Hendrick Motorsports engine operation alongside other Sunnen honing and engine building machines.

Read More6 Ways Electrification is Shifting Automotive Manufacturing

Trends to watch at IMTS: A Tier One transmission supplier weighs in on how hybrid and electric vehicles are changing the requirements for automotive component producers.

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreRead Next

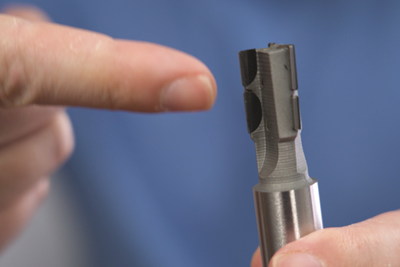

Video: 3D Printed Tool Illustrates the Impact of Additive Manufacturing on Machining

Is AM an aid to machining? A competitor? It’s both. The Cool Parts Show looks at a milling tool design made possible by 3D printing.

Read MoreGenerative Design Generates New Interest in a Range of Manufacturing Options

New developments in generative design can help companies make better decisions about part design by including manufacturability as a key value. CNC milling, for example, not an additive process, might come up as the better choice for making a complex part.

Read MoreVideo: Topology Optimization in Action

What is topology optimization, and how does it work? See the process for lightweighting a legacy part step-by-step using this design strategy in the video in this blog post.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)